TT4000 Series

Operating Instruction

11

4

Operating panel

The user can control the operation of the printer with the operating panel, for example:

•

pause, continue or cancel print jobs

•

set printing parameters, e.g. heating energy of the print head, print speed, configuration

of the ports, language and time (see “

Configuration Instructions

“)

•

start test functions (see “

Configuration Instructions

“)

•

control standalone operation with memory card (see “

Configuration Instructions

“)

•

perform a firmware update (see “

Configuration Instructions

“)

Several functions and settings can also be controlled via printer-specific commands with

software applications or via direct programming with a computer. Details on this can be

found in the “

Configuration Instructions

“.

The settings made at the operating panel are the basic settings of the label printer.

It is easier to make adjustments for different print jobs in the software whenever possible.

4.1

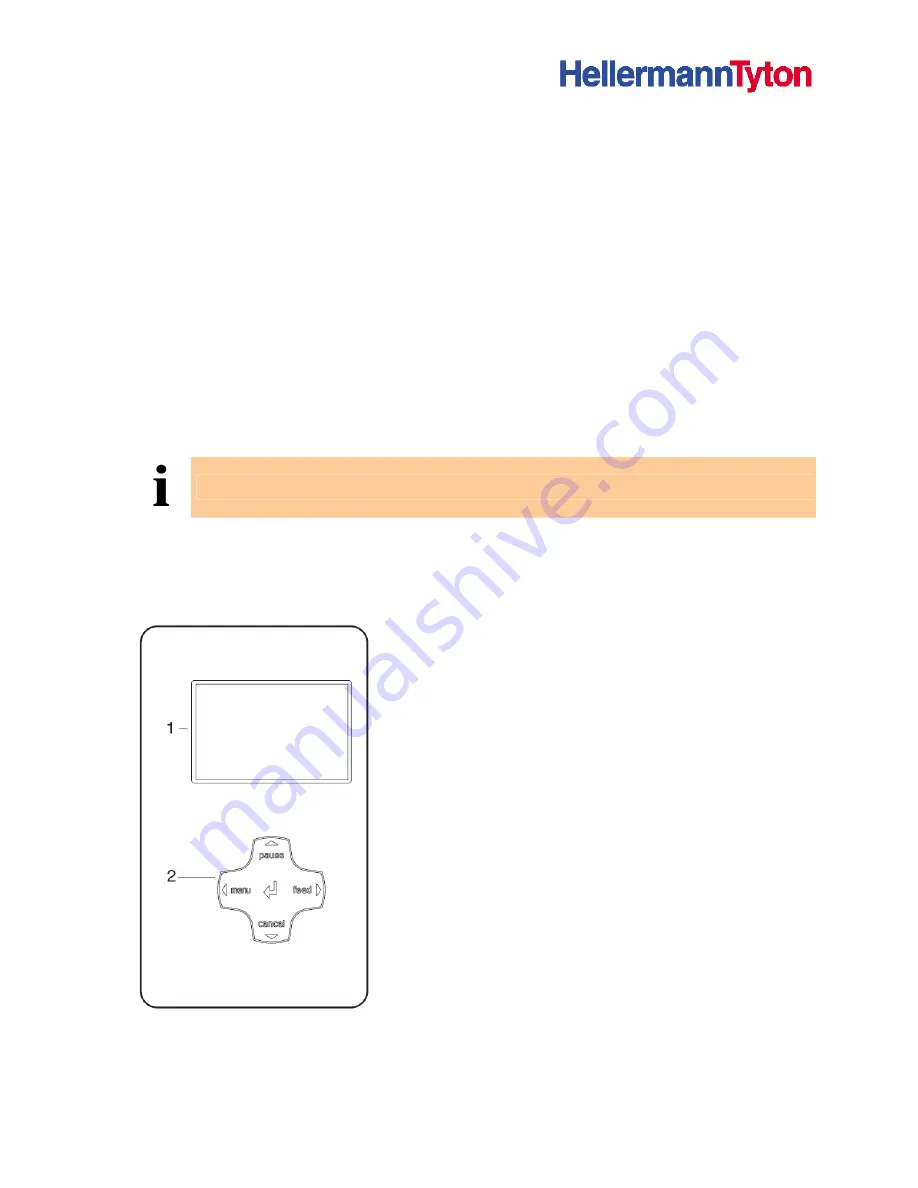

Layout of the operating panel

The operating panel is comprised of the graphical display

(1) and the navigator pad (2) with five integrated buttons.

The graphical display informs you of the current status of

the printer and the print job, reports errors and shows the

printer settings in the menu.

The button functions are dependent on the current printer

status: Active functions are indicated by the illuminated

letters and symbols on the buttons of the navigator pad.

While printing, active functions illuminate white (e.g. menu

or feed). Active functions are illuminated in orange in the

offline menu (arrows,

)

Functions of the buttons

pause, cancel, menu, feed buttons: (see 4.2.2 on page 13)

Arrows: Up, down, left and right in the menu tree.

button: Input of a parameter in the menu, calling up of

help in case of an error

Figure 3

Operating panel