INSTALLATION INSTRUCTIONS

Fan Coils: FEM4X, FEM4P, REM4X, FXM4X

2

496 01 5503 02

Specifications are subject to change without notice.

INTRODUCTION

Models FEM4X, FEM4P, and REM4X are for R

−

410A

refrigerant and can be used for upflow, horizontal left or right,

and downflow applications (accessory kit required for

downflow). These units leave the factory compliant with low

leak requirements of less than 2% cabinet leakage rate at 0.5

inches W.C. and 1.4% cabinet leakage rate at 0.5 inches

W.C. when tested in accordance with ASHRAE 193

standard.

FEM4P models are available for system sizes 1

−

1/2

−

4 tons

(18,000

−

48,000 BTUH) nominal cooling capacity. FEM4P

use a refrigerant piston metering device with an ECM.

FEM4X and FXM models are available for system sizes

1

−

1/2

−

5 tons (18,000

−

60,000 BTUH) nominal cooling

capacity. All models use an ECM motor and have a

factory

−

installed and appropriately sized hard shut

−

off TXV

metering device and are for R

−

410A refrigerant ONLY.

REM4X models are available for system sizes 1

−

1/2 through

5 tons (18,000

−

60,000 BTUH) nominal cooling capacity. All

models use an ECM motor and have a factory

−

installed and

appropriately sized hard shut

−

off R

−

410A TXV metering

device used for R

−

410A refrigerant ONLY.

FEM and REM models require a field supplied air filter.

Factory approved electric heater packages are available in

sizes 3kW through 30kW. See Product Specification

literature for available accessory kits.

LOCATION

Select the best position which suits the installation site

conditions. The location should provide adequate structural

support, space in the front of the unit for service access,

clearance for return air and supply duct connections, space

for refrigerant piping connections and condensate drain line

connections. If heaters are being installed make sure

adequate clearance is maintained from supply duct work.

NOTE

: If the door gasket is damaged or missing, the unit

may not meet the ASHRAE 193 standard for cabinet air

leakage. Contact your supplier and order kit #1191140.

Nuisance sweating may occur if the unit is installed in a high

humidity environment with low airflow. On these installations a

wrap of 2” (51mm) fiberglass insulation with a vapor barrier is

recommended.

NOTE:

Internal filter can be accessed from separate filter

door. If the filter can

NOT

be easily accessed, a remote filter

is recommended. Refer to ACCA Manual D for remote filter

sizing.

!

WARNING

FIRE HAZARD

Failure to maintain proper clearances could result in personal

injury, death, and/or property damage.

When heaters are installed, maintain clearances from com-

bustible materials as specified on unit rating plate. Do not use

plastic lined or combustible flexible ducting within 36 inches

of the supply end of the fan coil.

See Clearances

REQUIRED CLEARANCES

−

ALL MODELS inches

(mm)

No

Heaters

All Sides

0

From Supply Duct

0

With

Heaters

All Sides

0

From First 3 feet of Supply Duct to

Combustibles

1 (25)

From Supply Duct to Combustibles

after 3 feet

0

HEATER PACKAGES

Factory approved, field installed, UL listed heater packages

are available from the equipment supplier. See unit rating

plate for a list of factory approved heaters. Heaters that are

not factory approved could cause damage which would not

be covered under the equipment warranty.

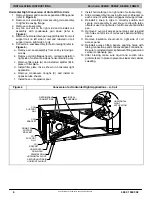

POSITION UNIT

Unit can stand or lie on floor, or hang from ceiling or wall.

Allow space for wiring, piping, and servicing unit.

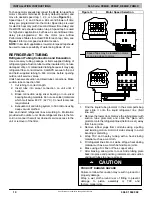

!

CAUTION

PROPERTY DAMAGE HAZARD

Failure to follow this caution may result in property

damage.

A field fabricated auxiliary drain pan, with a separate drain

is REQUIRED for all installations over a finished living

space or in any area that may be damaged by overflow

from a restricted main drain pan. In some localities, local

codes require an auxiliary drain pan for ANY horizontal

installation.

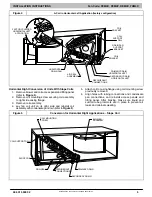

Figure 1

Modular Unit Assembly

2 SCREWS

2 SCREWS

REAR CORNER

BRACKET

BLOWER BOX

COIL BOX

2 SCREWS