17

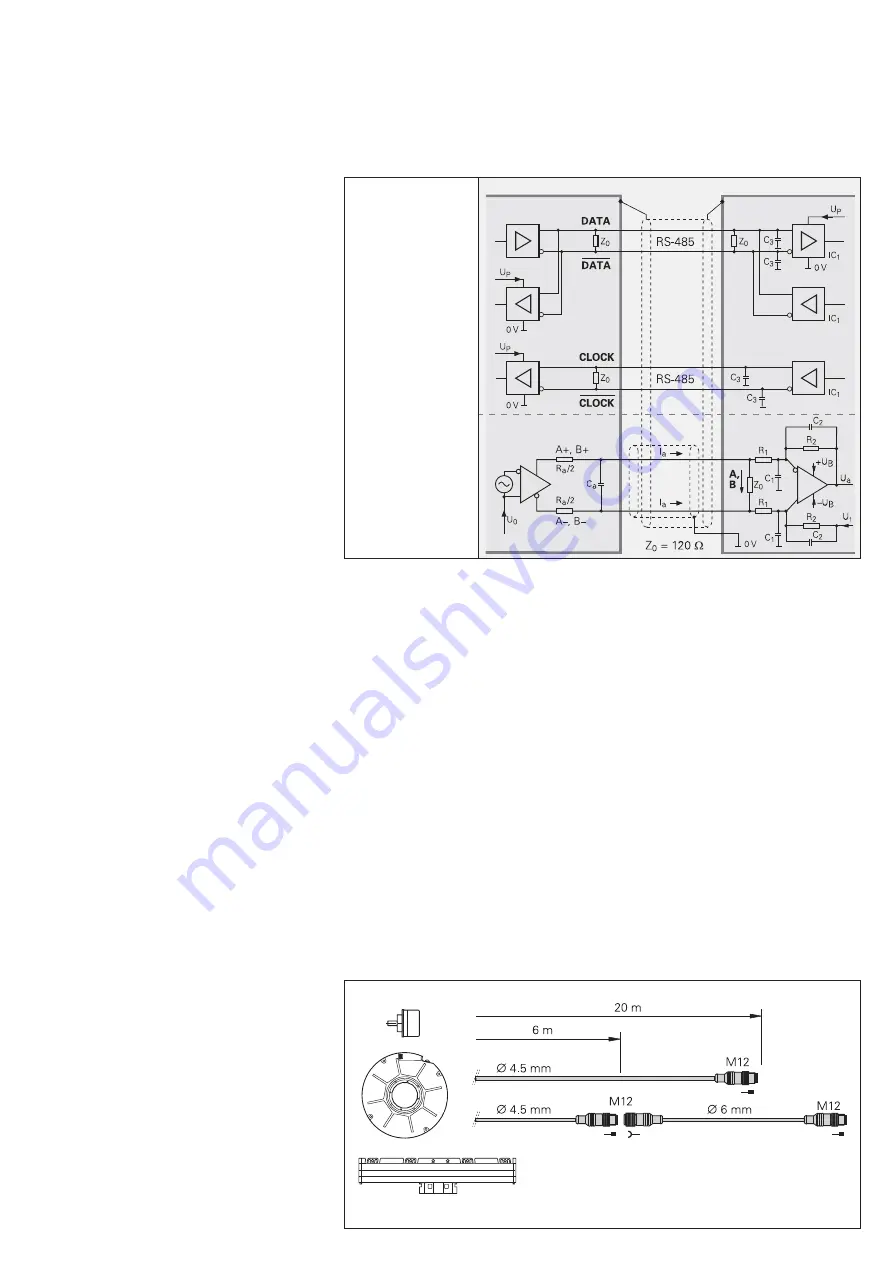

Data (measured values or parameters) can

be transferred bidirectionally between

position encoders and subsequent

electronics with transceiver components in

accordance with RS-485 (differential

signals), in synchronism with the clock

signal (CLOCK) produced by the

subsequent electronics.

Dimensioning

IC

1

= RS 485 differential line receiver and

driver

C

3

= 330 pF

Z

0

= 120

−

Encoder

Subsequent electronics

Input Circuitry of the Subsequent Electronics

Data transfer

Incremental signals

depending on

encoder

Connecting elements

For the encoders with EnDat 2.2 interface

without incremental signals, 8-pin M12

connecting elements are used. M12

connector technology is in wide use in

industrial applications and has the following

advantages:

Cost-effective connection technology

•

Smaller dimensions

•

Simpler cable feed through in machines

•

Thinner connecting cables (

•

¬

6 mm

instead of the previous 8 mm)

Higher reliability thanks to injection-

•

coated connection technology

Integrated lock mechanism as vibration

•

protection

Connection Technology

Cables

Transmission frequencies up to 16 MHz in

combination with large cable lengths place

high technological demands on the cable.

HEIDENHAIN cables are equal to this task,

not least because of a cable construction

conceived specifi cally for this application.

We recommend using original

HEIDENHAIN cable.

Due to the data transfer technology, the

adapter cable connected directly to the

encoder (

¬

†

4.5 mm) must not be longer

than 20 m. Greater cable lengths can be

realized with a max. 6 m adapter cable and

an extension cable (

¬

6 mm).