23

®

Link

Heat

Stk #

Size

Dimension X

11328

1"

13" ± 1⁄4" (330 ± 5 mm)

11335

11⁄4"

12-1⁄2" ± 1⁄4" (320 ± 5 mm)

11341

11⁄2"

12-3⁄4" ± 1⁄4" (325 ± 5 mm)

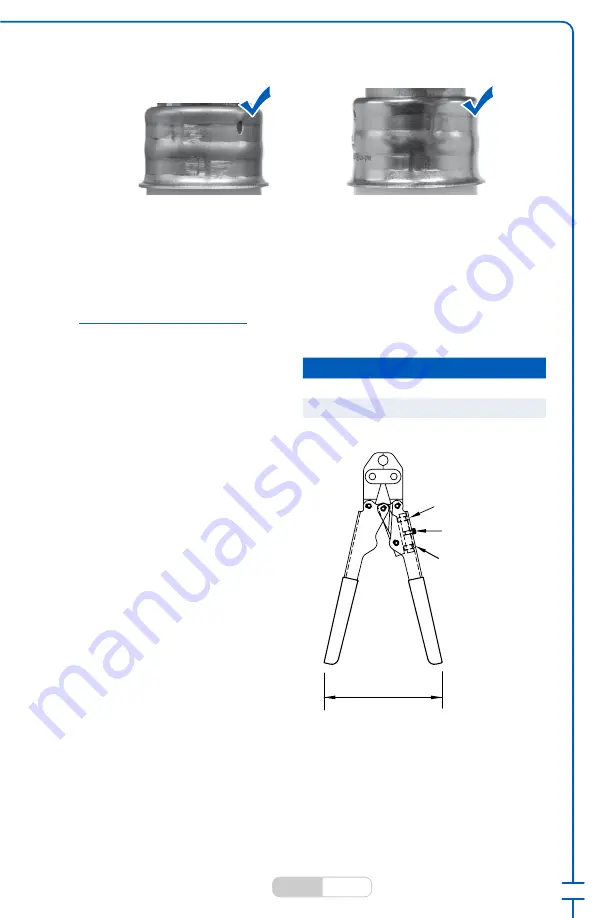

1", 11⁄4", & 11⁄2" Standard Press Tool Calibration

1. Close the tool handles until preload

is reached (point at which the jaws

butt together).

2. Measure Dimension X (see diagram

below) and compare against

the measurements listed in the

corresponding table below and

on the tool's adjustment sticker,

located on the handle (this sticker

supersedes information in this

manual).

3. To adjust the preload setting, loosen

the bottom set screw slightly by

turning counter clockwise. Tighten

the top set screw by turning

clockwise, or loosen by turning

counter-clockwise, until the preload

distance is within tolerance for

Dimension X. Tighten the bottom

set screw to clamp the setting.

4. Lubricate all joints and pivot points.

5. Make 3 test presses, testing each

with a Go/No-Go Gauge, to ensure

the tool is not damaged or worn.

Worn tools can often be refurbished

with new pins and clips HL Part #:

11903.

6. Recalibrate as needed.

All HeatLink Press Tools are precalibrated by the manufacturer, and do not normally require

an initial calibration. However, all press tools wear with use, and it is recommended that

every press tool be recalibrated as necessary.

A

calibration demonstration video

is available on the HeatLink website.

Standard Press Tools

11⁄4"

11⁄2"

Example Presses

Warranty is null and void if the date coded adjustment sticker is removed from the tool.

Never exceed the specified handle distance or premature wear will result.

New tools may slightly exceed Dimension X until broken in by use.

Always wear eye protection when working with the HeatLink® press tool and fitting system.

DIMENSION X

top set screw

frame screw

(do not loosen)

bottom screw

(clamping)

Handle Preload