HeatLink

®

Mixing Valve Reset Control Stk# 31360

®

Link

Heat

www.heatlinkgroup.com

H

e

a

tL

in

k

8

Characterized Heating Curve

The characterized Heating Curve takes into account the type of terminal unit that the system is using. Since different types of terminal units transfer

heat to a space using different proportions of radiation, convection and conduction, the supply water temperature must be controlled differently.

Once the control is told what type of terminal unit is used, the control varies the supply water temperature according to the type of terminal unit.

This improves the control of the air temperature in the building.

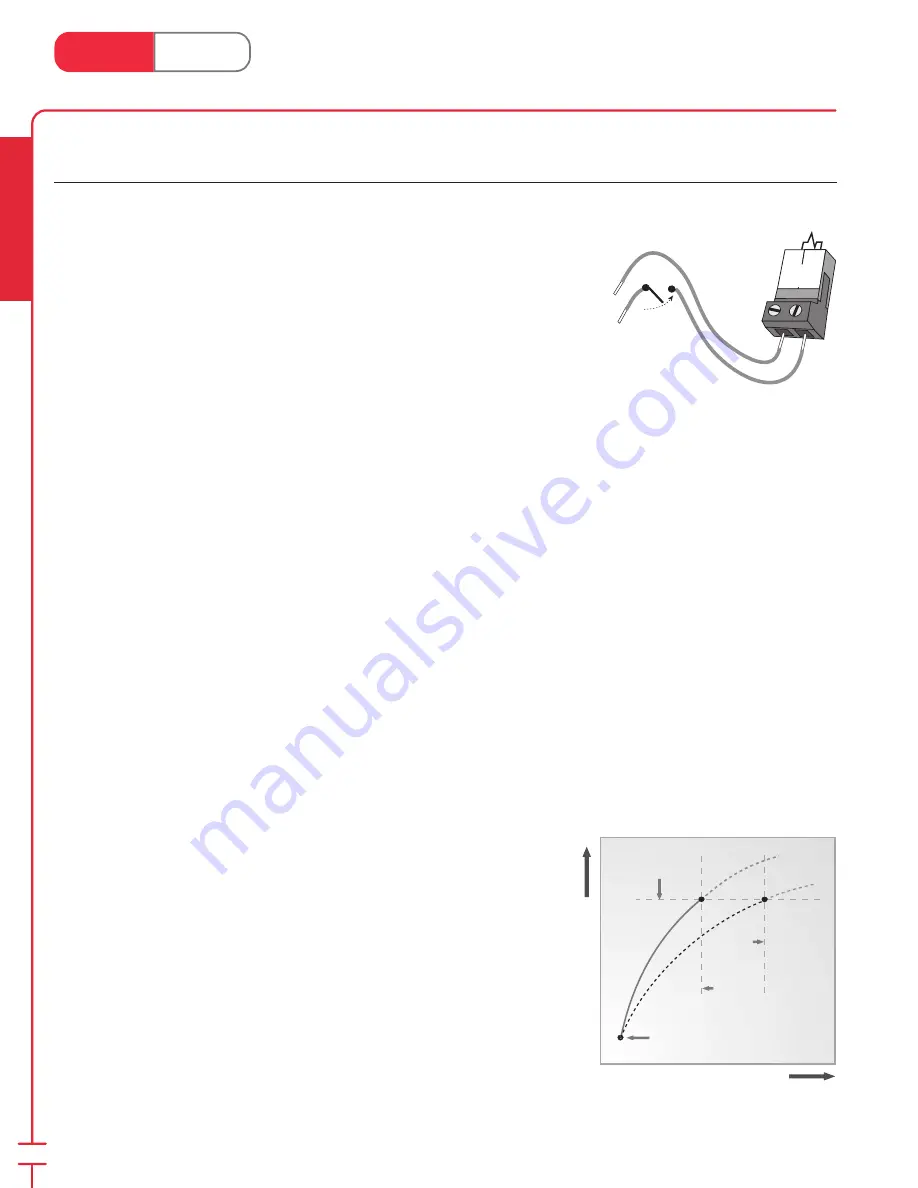

Outdoor Design (OUTDR DSGN)

The OUTDR DSGN is the outdoor air temperature that is the typical coldest temperature of the

year where the building is located. This temperature is used when doing the heat loss calculations

for the building. If a cold outdoor design temperature is selected, the mixing supply temperature

rises gradually as the outdoor temperature drops. If a warm outdoor design temperature is selected,

the mixing supply temperature rises rapidly as the outdoor temperature drops.

Decreasing Outdoor Temperature

Increasing

W

ate

r

Temperatur

e

cold

MIX INDR

MIX DSGN

warm

OUTDR

DSGN

Mixing Operation (European Version)

Mixing Target Temperature (MIX TARGET)

When used as a mixing reset control, The MIX TARGET temperature is calculated from the Characterized Heating Curve settings, outdoor air

temperature and optionally, indoor air temperature. When used as a setpoint control, the installer sets the MIX TARGET temperature. The control

displays the temperature that it is currently trying to maintain as the mixing supply temperature. If the control does not have a mixing demand,

“- - -” is displayed as the MIX TARGET.

System Pump Operation (Sys Pmp)

The system pump contact (Sys Pmp, terminal 5) closes whenever there is a mixing demand and the

Stk# 31360 is not in WWSD. The system pump segment is displayed in the LCD. After the mixing

demand has been satisfied, the Stk# 31360 continues to operate the system pump for 20 seconds. This allows some residual heat to be purged out

to the heating system. During WWSD, the system pump is operated based on the exercise function.

Indoor Sensor

An indoor sensor may be used in order to provide indoor temperature feedback. The indoor sensor is connected to the Com and Indr terminals (16

and 18). In addition, power must be applied to the

Mixing Demand

terminals (1 and 2) as described in the MIXING DEMAND section. With the

indoor sensor connected, the Stk# 31360 is able to sense the actual room temperature. Indoor temperature feedback fine-tunes the supply water

temperature in the mixing system to maintain room temperature. To adjust the room temperature, use the ROOM OCC or ROOM UNOCC setting

in the ADJUST menu at the control. Feedback fine-tunes the supply water temperature in the mixing system to maintain room temperature. To

adjust the room temperature, use the ROOM OCC or ROOM UNOCC setting in the ADJUST menu at the control.

If a multiple zone system is used with an indoor sensor, proper placement of the indoor sensor is essential. The indoor sensor should be located in

an area which best represents the average air temperature of the zones.

Mixing Demand

A mixing demand is required in order for the Stk# 31360 to provide heat. A mixing demand is

generated by applying a voltage of 24 V (ac) or 24 V (dc) across the Mixing Demand terminals

(1 and 2). Once voltage is applied, the Mixing Demand pointer is displayed in the LCD. If the

Stk# 31360 is not in WWSD, the Stk# 31360 closes the Sys Pmp contact. The Stk# 31360 calculates

a MIX TARGET supply temperature based on the outdoor air temperature and settings. If required,

the Stk# 31360 operates the boiler in order to provide heat to the mixing valve.

1

2

Mixing

Demand

24 V (ac) or

24 V (dc)

European Version

Mixing Operation

General

Installer

Summary of Contents for 31360

Page 29: ...This page is intentionally blank...

Page 33: ...This page is intentionally blank...