28

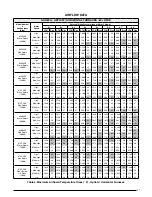

GUH80A - UPFLOW / HORIZONTAL FURNACES - 80+ AFUE

Model Number

&

Heating Input

(Btuh)

Motor

Speed

External Static Pressure (Inches Water Column)

0.1

0.2

0.3

0.4

0.5

0.6

0.7

0.8

CFM

Rise

CFM

Rise

CFM

Rise

CFM

Rise

CFM

Rise

CFM

Rise

CFM

Rise

CFM

Rise

090C5XE

Bottom Return

(90,000)

High*

1,940

34

1,860

36

1,790

37

1,710

39

1,625

41

1,540

43

1,450

46

1,355

49

Med-High**

1,820

37

1,760

38

1,695

39

1,620

41

1,545

43

1,466

45

1,380

48

1,280

52

Med-Low

1,290

52

1,245

54

1,200

56

1,155

58

1,110

60

1,060

63

995

67

915

73

Low

1,145

58

1,110

60

1,070

62

1,035

64

1,000

67

950

70

905

74

835

80

090C5XE

Side Return

(90,000)

High*

2,020

33

1,935

34

1,860

36

1,780

37

1,690

39

1,600

42

1,510

44

1,410

47

Med-High**

1,895

35

1,830

36

1,765

38

1,685

40

1,610

41

1,525

44

1,435

46

1,330

50

Med-Low

1,345

50

1,295

51

1,250

53

1,200

56

1,155

58

1,100

61

1,035

64

950

70

Low

1,190

56

1,155

58

1,115

60

1,075

62

1,040

64

980

68

940

71

870

77

090C5XE

Side + Bottom

or 2 Sides

(90,000)

High*

2,040

33

1,955

34

1,880

35

1,795

37

1,705

39

1,620

41

1,525

44

1,425

47

Med-High**

1,910

35

1,850

36

1,780

37

1,700

39

1,625

41

1,540

43

1,450

46

1,345

50

Med-Low

1,355

49

1,310

51

1,260

53

1,215

55

1,165

57

1,115

60

1,050

63

960

69

Low

1,205

55

1,165

57

1,125

59

1,085

61

1,050

63

1,000

67

950

70

875

76

108C5XE

Bottom Return

(108,000)

High*

2,205

36

2,150

37

2,095

38

2,030

39

1,970

41

1,900

42

1,830

44

1,740

46

Med-High**

2,050

39

1,995

40

1,955

41

1,895

42

1,840

43

1,775

45

1,700

47

1,610

50

Med-Low

1,700

47

1,680

48

1,645

49

1,610

50

1,565

51

1,525

52

1,460

55

1,375

58

Low

1,390

58

1,370

58

1,355

59

1,320

61

1,300

62

1,270

63

1,225

65

1,175

68

108C5XE

Side Return

(108,000)

High*

2,295

35

2,235

36

2,180

37

2,110

38

2,050

39

1,975

41

1,900

42

1,810

44

Med-High**

2,130

38

2,075

39

2,035

39

1,970

41

1,915

42

1,845

43

1,765

45

1,675

48

Med-Low

1,770

45

1,750

46

1,710

47

1,675

48

1,630

49

1,585

50

1,520

53

1,430

56

Low

1,445

55

1,425

56

1,410

57

1,375

58

1,350

59

1,320

61

1,275

63

1,225

65

108C5XE

Side + Bottom

or 2 Sides

(108,000)

High*

2,315

35

2,260

35

2,200

36

2,130

38

2,070

39

1,995

40

1,925

42

1,825

44

Med-High**

2,155

37

2,095

38

2,055

39

1,990

40

1,930

41

1,865

43

1,785

45

1,690

47

Med-Low

1,785

45

1,765

45

1,725

46

1,690

47

1,645

49

1,600

50

1,535

52

1,445

55

Low

1,460

55

1,440

56

1,425

56

1,385

58

1,365

59

1,335

60

1,285

62

1,235

65

126D5XE

Bottom only

or 2 openings

(126,000)

High*

2,255

41

2,200

42

2,125

44

2,065

45

2,010

46

1,935

48

1,855

50

1,755

53

Med-High**

2,075

45

2,025

46

1,970

47

1,940

48

1,875

50

1,810

52

1,750

53

1,680

56

Med-Low

1,720

54

1,695

55

1,655

56

1,630

57

1,580

59

1,520

61

1,455

64

1,390

67

Low

1,360

69

1,375

68

1,365

68

1,315

71

1,310

71

1,300

72

1,260

74

1,230

76

126D5XE

Side Return

(126,000)

High*

2,230

42

2,180

43

2,105

44

2,045

46

1,990

47

1,915

49

1,835

51

1,740

54

Med-High**

2,055

45

2,005

47

1,950

48

1,920

49

1,855

50

1,790

52

1,735

54

1,665

56

Med-Low

1,705

55

1,680

56

1,640

57

1,615

58

1,565

60

1,505

62

1,440

65

1,375

68

Low

1,345

69

1,360

69

1,350

69

1,300

72

1,230

76

1,290

72

1,250

75

1,220

77

NOTES

:

* Factory Set Cooling Speed

** Factory Set Heating Speed

1. Two openings are recommended for airflows above 1,600 CFM if filter(s) is(are) adjacent to furnace

2. Temperature rises in the table are approximate. Actual temperature rises may vary.

3. Temperature rises shaded in gray are for reference only. These conditions are not recommended.

Table 3. Continued