Page 20

12/12

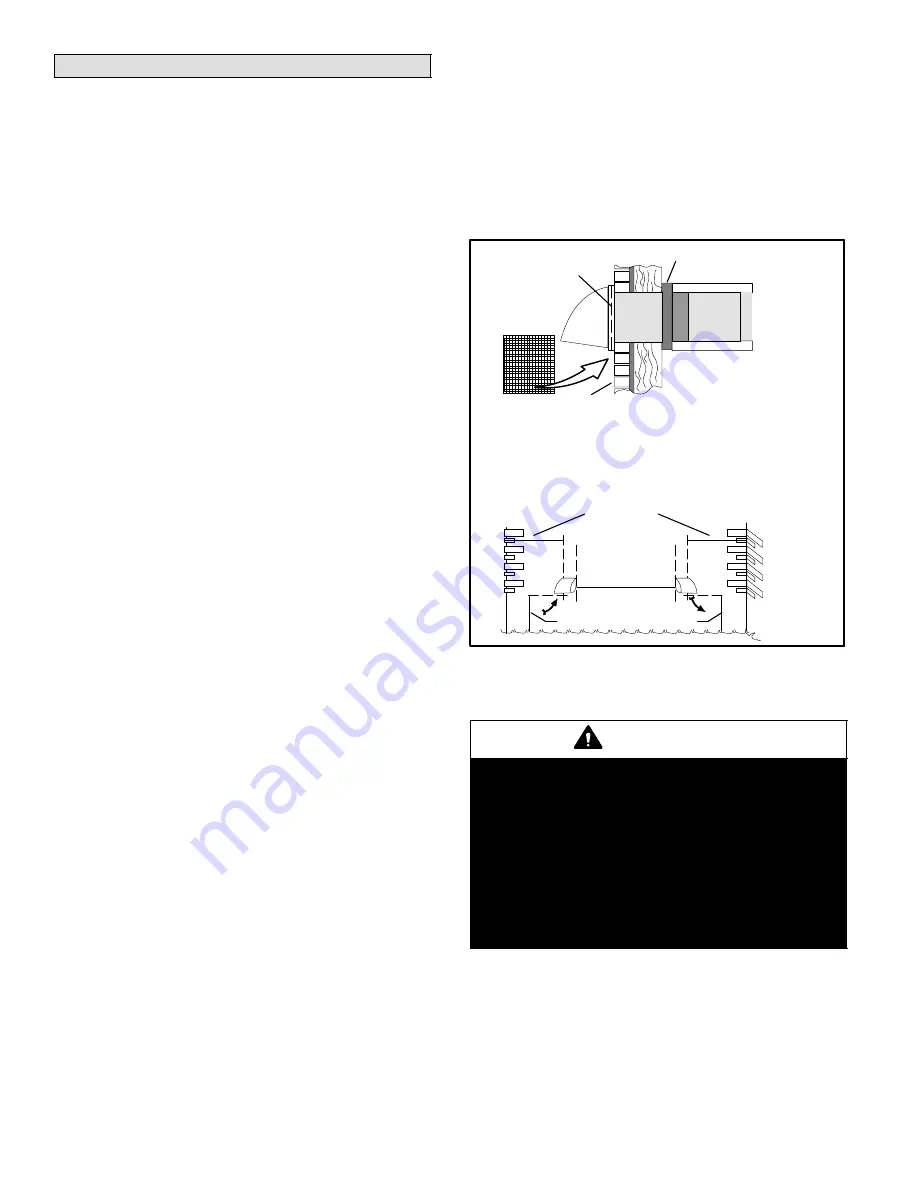

Installing Weatherhoods

Installing Ducting from Weatherhoods to the

(HRV/ERV) Unit

The inner and outer liners of the flexible insulated duct

must be clamped to the sleeve of the weatherhoods (as

close to the outside as possible) and the appropriate port

on the HRV/ERV. It is very important that the fresh air in-

take line be given special attention to make sure it is well

sealed. A good bead of high quality caulking (preferably

acoustical sealant) will seal the inner flexible duct to both

the HRV/ERV port and the weatherhood prior to clamping.

To minimize airflow restriction, the flexible insulated duct

that connects the two outside weatherhoods to the

HRV/ERV unit should be stretched tightly and be as short

as possible.

Twisting or folding the duct will severely restrict airflow.

Hard (rigid) ducting which has been sealed and insulated

should be used for runs over 10’ (3.3m). Refer to local

building codes.

Intake Weatherhood Requirements

Observe the following when installing the intake weather-

hood:

1. Should be located upstream (if there are prevailing

winds)

2. At least 6’ (2m) from the exhaust weatherhood

3. At least 6’ (2m) away from dryer vents and furnace ex-

haust (medium or high efficiency furnaces)

4. A minimum of at least 6’ (2m) from driveways, oil fill

pipes, gas meters, or garbage containers

5. At least 18" (457mm) above the ground, or above the

depth of expected snow accumulation

6. At least 3’ (1m) from the corner of the building

7. DO NOT locate in a garage, attic or crawl space

8. AFTER installing the weatherhood, its outside perime-

ter must be sealed with exterior caulking

Exhaust Weatherhood Requirements

Observe the following when installing the exhaust

weatherhood:

1. At least 6’ (2m) from the ventilation air intake

2. At least 18" (457mm) above ground or above the depth

of expected snow accumulation

3. At least 3’ (1m) away from the corner of the building

4. Not near a gas meter, electric meter, or a walkway

where fog or ice could create a hazard

5. Not into a garage, workshop, or other unheated space

6. AFTER installing the weatherhood, its outside perime-

ter must be sealed with exterior caulking

Weatherhoods

Fixed covered weatherhoods have a built−in bird screen

with a

¼

" (6mm) mesh to prevent foreign objects from en-

tering the ducting labeled SUPPLY and EXHAUST.

5" (127 mm) Part no.

92E66

6" (152 mm) Part no.

95P07

7" (203 mm) Part no.

17N11

ÑÑÑÑ

ÑÑÑÑ

ÑÑÑÑ

1. Thermal collar slides over galvanized sleeve of weatherhood.

2. Fasten thermal collar to belt.

3. Slide insulated flexible ducting over the weatherhood’s galvanized sleeve and fasten

to the thermal collar.

4. Hood is hinged to allow for easy access for cleaning screen.

12" galva-

nized pipe

supplied

Collar is supplied to ensure

vapor barrier is 100% sealed

to wall plate.

SCREEN

(side view)

EXTERIOR

WALL

1/4" (6mm)

SCREEN

(front view)

6’ (2m) min.

recommended

36" (1m) min.

recommended

OUTSIDE

CORNER

INSIDE

CORNER

18" (460Mm) min. recommended

SUPPLY

EXHAUST

Figure 17. Weatherhood Installation

CAUTION

Potential equipment malfunction or damage.

May require repairs and/or void warranty.

Snow accumulation may block airway of weather-

hoods. Install intake and exhaust weatherhoods at

least 18 inches (457 mm) above the ground or above

the depth of expected snow accumulation.

Install intake and exhaust weatherhoods with at

least 6 feet distance between openings to prevent

short circuit air routes. Local codes may require a

greater distance between openings.