15

U9B

A0137-7.0 en/de/fr

HBM

with the tightening torques and information provided in section 5.3 when

mounting.

NOTE

When locking, the tightening torque must not be shunted through the trans

ducer. Also note the limit values for bending moments and lateral forces.

5.5

Installation with knuckle eyes

Knuckle eyes prevent the application of torsional moments and, where two

knuckle eyes are used, bending moments, together with lateral and oblique

loads in the transducer. They are suitable for use with quasi‐static loads (load

cycles

v

10 Hz). Pliable tension/compression bars should be used for dy

namic loads with higher frequencies (see section 5.3).

5.5.1 Installation and locking with initial stress

(recommended installation variant)

1. Screw the transducer locknut fully into the threaded connector.

2. Screw the knuckle eye as far as possible onto the transducer.

3. Unscrew the knuckle eye again 1 to 2 threads and align.

4. Pre‐stress the transducer to 110% operating load in tensile direction.

5. Tighten the locknut by hand.

6. Relieve the transducer.

5.5.2 Installation and locking with tightening torque

1. Screw the transducer locknut fully into the threaded connector.

2. Screw the knuckle eye as far as possible onto the transducer.

3. Unscrew the knuckle eye again 1 to 2 threads and align.

4. Tighten the locknut with the torque specified in the following table.

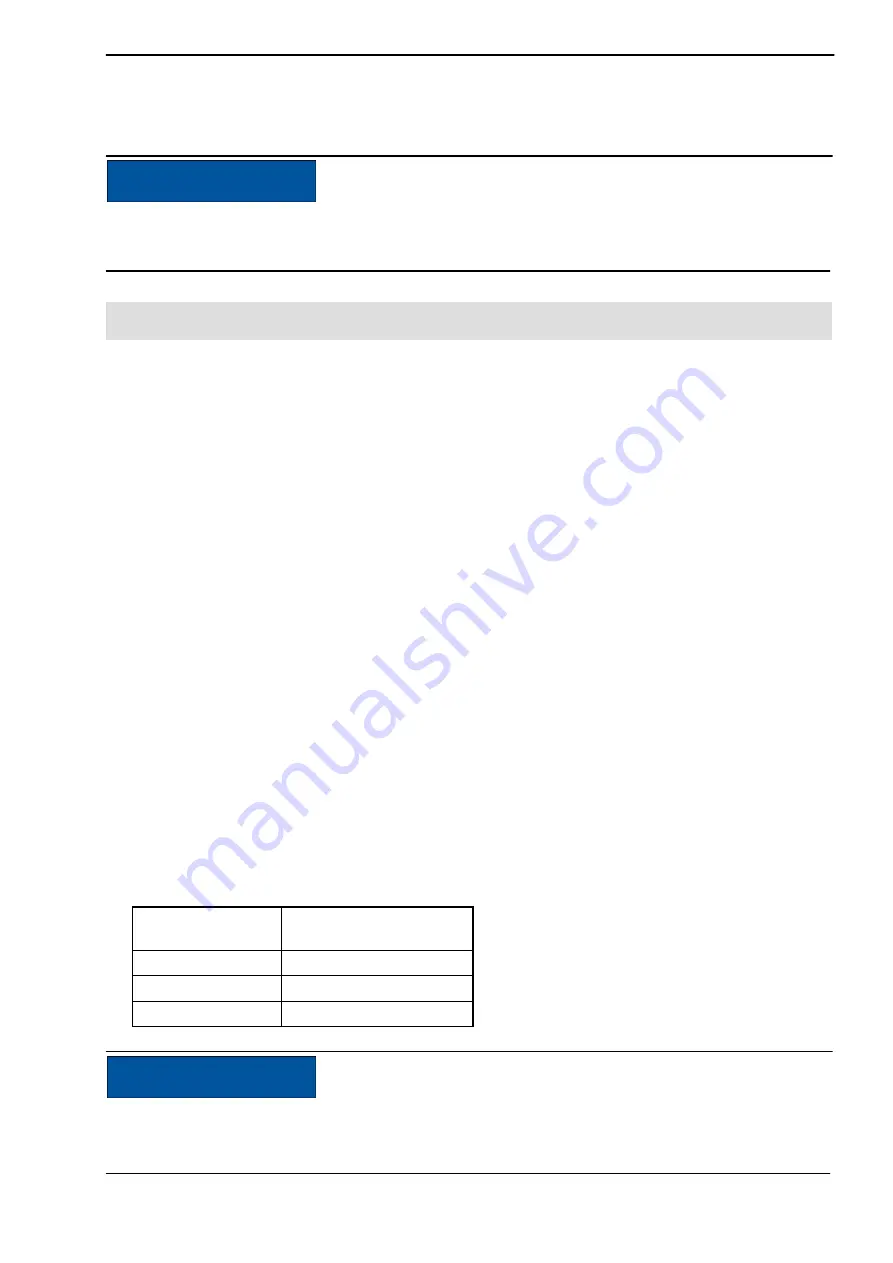

Nominal (rated)

force

Tightening torque

(N

⋅

m)

50N

…

1kN

8

2

…

20 kN

40

50kN

200

NOTE

When locking, the tightening torque must not be shunted through the trans

ducer. Also note the limit values for bending moments and lateral forces.

Summary of Contents for U9B

Page 2: ...English Seite 3 22 Deutsch Page 23 44 Fran ais Page 44 66...

Page 22: ...U9B 22 A0137 7 0 en de fr HBM...

Page 44: ...U9B 44 A0137 7 0 en de fr HBM...

Page 67: ......