MACH

®

Gas Fired Boiler

31

3.9.4 Test of Gas Pressure Switches

Low Gas Pressure Switch

The boiler is furnished with a low gas pressure switch. The operation of this switch must be checked by slowly closing

the main gas cock while the burner is operating. The switch should shut down the main burner. When the gas

pressure switch opens, a manual reset lockout displaying LOCKING LOW GAS PRESSURE on the display panel will

occur. Upon re-opening the main gas cock, the LOCKING LOW GAS PRESSURE will remain on until the display

panel is manually reset.

High Gas Pressure Switch

The boiler is furnished with a high pressure switch that must be checked by closing the downstream gas cock with the

boiler off. When the boiler is started, it should enter its normal starting cycle and fail on high gas pressure when the

automatic gas valves open. The boiler locks out and displays LOCKING HIGH GAS PRESSURE on the display

panel. Upon re-opening the gas cock, the LOCKING HIGH GAS PRESSURE indicator will remain on until the display

panel is manually reset.

3.10 I

NITIAL

A

DJUSTMENTS

3.10.1

Operating Temperature Controller

The MACH

®

boiler C750-1050 is equipped with

ENVI

®

control; an intelligent control system with

advanced features such as text-based display,

communication capabilities, and boiler

sequencing. Errors are date and time stamped

providing built-in history of boiler status and

performance. This control constantly tracks the

load by recording burner high, low and mid run

hours. One control to do it all – temperature

control, flame safeguard, firing rate control,

blocked flue protection, outdoor air reset, freeze

protection, built-in cascade sequencing, MODBUS

communication and more.

The user should

become thoroughly familiar with the

operation of the boiler and controls before

attempting to make any adjustments.

The boiler control has a text display panel. The display panel is used to setup and monitor boiler operation by means

of six push buttons MENU, BACK, ENTER, UP, DOWN, and RESET as shown above. The buttons across the bottom

are used to navigate through the various screens. The four line screen shows boiler operating information on various

screens. The display screen is backlit for ease of viewing. Pressing any key will illuminate the backlight.

The standby screen is shown upon startup. This screen shows the date, time, boiler status, supply temp and setpoint

temp. Pushing the menu button displays a menu of options.

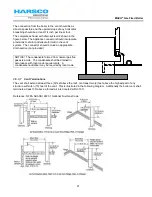

The menu includes access to the Standby, Information, Errors,

Program Parameters, Configuration, Cascade, and Service

Menu. The Up and Down buttons are used to position the arrow

next to the desired option and the enter button is pushed to enter

that option. The list is displayed and may have more than four

lines. Use the down arrow to view the complete list.

Menu

Standby

Information

Errors

Menu

Standby

Information

Errors