MACH

®

Gas Fired Boiler

16

E. When a duct is used to meet the requirement for combustion air supply, as described in paragraphs A through D,

above, the opening of the duct shall be located so there is no possibility of cold air affecting steam or water piping,

electrical equipment or mechanical equipment.

F. When combustion air is supplied by mechanical means, an airflow-sensing device must be installed. It must be

wired into the pre-ignition limit string to prevent the burner from starting or to stop an operating burner in case of

air supply failure.

G. When all combustion air is supplied through a make-up air heater, and the appliance is interlocked to the heater,

the requirements of paragraphs A through F do not apply.

NOTICE!

1. The free area of a combustion air supply opening is calculated by deducting the blockage area of any fixed

louvers, grilles or screens from the total area of the opening.

2. Screens shall be not smaller than ¼”

3. Motorized louvers shall be interlocked with the appliance so that they are proven open prior to main burner

ignition and operation

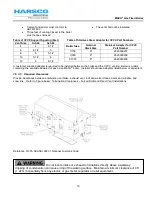

Table of Canadian Minimum Area of Combustion and Ventilation Air Openings

MACH

®

Boiler

Required Combustion Air

Opening

Ventilation Air Opening

Model #

Input (Btu/Hr)

in

2

mm

2

in

2

mm

2

C750

750,000

25

16,129

10

6,452

C900

900,000

30

19,355

10

6,452

C1050

1,050,000

35

22,581

10

6,452

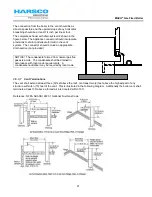

3.5.3 Flue Venting

This boiler is not certified for use with Type "B" vent nor with PVC venting.

3.5.3.1

VENT SIZING

The vent must be sized in accordance with the ASHRAE Systems and Equipment handbook, Chapter 30 or according

to the vent manufacturer’s recommendations. When using manufactured venting systems, consult your vent supplier

for correct sizing and structural support requirements.

Table of Vent Design Parameters

MACH

®

Boiler

Model

Frictional

Resistance

Stack

Temperature

CO

2

Natural Gas

CO

2

LP Gas

C750 – C1050

0.22”

210°F

9.0%

10.4%

3.5.3.2

CATEGORY II INSTALLATIONS

The MACH C750, C900 and C1050 are dual-certified for both Category II and Category IV operation. Category II

appliances operate with a non-positive vent static pressure and with a vent temperature that may cause excessive

condensate production in the vent. There are several requirements for reliable operation of the boilers under

Category II conditions:

All boiler venting systems should be designed by a qualified venting

professional experienced in venting system design. The information contained herein should

be used as a guide only and is not intended to be used in lieu of qualified technical expertise.