MACH

®

Gas Fired Boiler

27

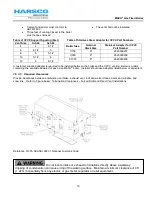

Delta pressure loss in pressure at a flow rate

3.7.1.1

Piping with Refrigeration Machines

When installed in a two-pipe system that provides both chilled and hot water, the control system should be configured

so as to limit the time rate of change of temperature at the boiler. Consult your authorized Harsco Industrial,

Patterson-Kelley boiler representative for application guidance.

3.7.1.2

Piping with Air Handling Units

The boiler piping system of a hot water heating boiler connected to heating coils located in air handling units, where

they may be exposed to refrigerated air circulation, must be equipped with flow control valves or other automatic

means to prevent gravity circulation of the boiler water during the cooling cycle.

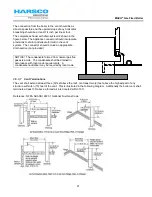

3.7.2 Boiler Inlet and Outlet Connections

All water connections should be in compliance with

national, state and local code requirements.

Adapters from Victaulic to NPT are available from Harsco

Industrial, Patterson-Kelley.

The bottom connection to the boiler is the INLET and

must be used for the return from the system.

The top connection to the boiler is the OUTLET and must

be connected as the supply to the system.

Flow vs. DP

0

2

4

6

8

10

12

14

0

20

40

60

80

100

120

Flow (gpm)

DP (ft)

Isolating

Valve

Strainer

Relief Valve

Isolating Valve

Outlet

(to system)

Inlet

(from system)

Boiler

Drain

Valve

Condensate

Trap (Piped to

drain)*

Building

Drain

NOTICE! The boiler is furnished with 2” grooved

connections and Victaulic Style 75 Couplings.

These couplings must be used with the EPDM

Victaulic seals. Isolating valves must be installed

in both water connections.

NOTICE! Condensate Trap must be piped to

drain in accordance with all national, state and

local codes. If installed outdoors, it must be field

heat traced.

C750

C900

C1050