WARNING

NEVER ATTEMPT TO OPERATE THE

TRANSMITTER WITH ANY PA TRANSIS-

TORS REMOVED. IF REPLACEMENTS

ARE NOT AVAILABLE, IT IS NECESSARY

TO LEAVE THE SHORTED ONES IN CIR-

CUIT. THIS WILL KEEP THE TOROIDAL

COMBINING IN TACT, AND WILL NOT IM-

PAIR OPERATION OF THE TRANSMITTER

AT A REDUCED POWER LEVEL.

C.5.

Handling MOSFET’s

Due to the fragile nature of the gate of a

MOSFET, special care in their handling is

required. The gate can be destroyed by an

electrostatic discharge. Please read the en-

closed Technical Brief discussing safe han-

dling of transistors and integrated circuits.

Among other aspects of ESD control, this

publication covers the use of conductive

packaging and antistatic wrist bands.

NOTE

MOSFET transistors which are in circuit

in the GATES Series™ transmitters are

immune to this damage.

The MOSFET transistors are shipped in

antistatic packaging. The transistors should

remain in this packaging until they are to be

used or tested.

C.6.

Testing MOSFET’s

The MOSFETS used in the GATES Se-

ries™ transmitters may be checked with an

ohmmeter. However there is a requirement

which restricts the use of some ohmmeters.

If the battery voltage is too low (under 3V)

or too high (over 20V) the ohmmeter cannot

be used. A battery voltage less than 3V will

not give an operational check of the transis-

tor and a battery voltage greater than 20V

may result in damage to the transistor under

test. A Simpson 260, which uses a 9V bat-

tery on the Rx10k scale works quite well.

The following test applies to all MOS-

FETS used in the transmitter, but is not

necessarily applicable to MOSFETS used

in other equipment.

This test will show how a MOSFET can

be switched “on” and “off” by charging and

discharging the gate of the MOSFET.

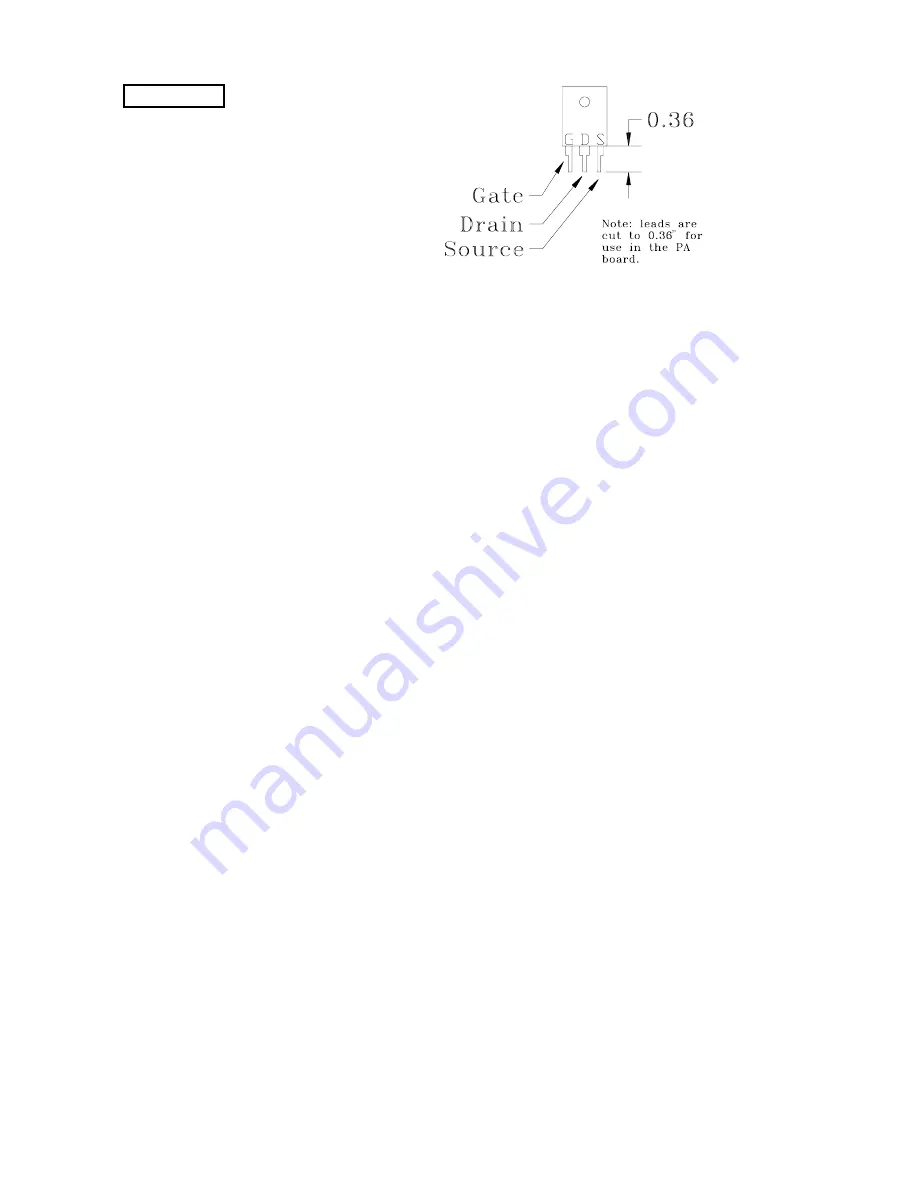

Refer to Figure C-1 for the following test.

Connect the positive lead of the ohmmeter

to the source of the transistor. Momentarily

connect the negative lead to the gate and

then connect it to the source. Then connect

the positive lead to the drain (middle lead).

The ohmmeter should read at least 2 me-

gohms.

Remove the positive lead from the drain

and momentarily touch it to the gate. Re-

connect the positive lead to the drain. The

ohmmeter should read very near zero ohms.

C.6.1.

Replacing PA Transistors

Although there is no adhesive used in

attaching the transistors, you may find that

they remain in place after the mounting

screw is removed, and the terminals are

loosened. However, the transistors should

easily pop loose if you apply some leverage

to the transistor case. One way to do this is

to insert the shaft of a small screwdriver into

the mounting hole, then gently pry with the

screwdriver.

When installing new transistors, trim the

lead length so that the leads extend well into

the terminal blocks, but not so far as to bear

against the back end. A length of 0.36"

works well.

Tighten the transistor mounting screw

first, to no more than 5 inch-pounds.

Tighten the terminal block screws only after

the mounting screw has been tightened.

C.7.

Scoping the RF Drive

Measuring the RF drive with a scope can

be very meaningful in terms of identifying

blown transistors or a general RF drive

problem.

A failed PA transistor will usually cause

the RF drive level for that particular pair of

transistors to drop to a very low value. For

this reason, checking the drive levels on the

PA module(s) can help to readily identify

shorted transistors.

If a large number of PA transistors were to

short, it would possibly load down the entire

drive system. This will cause all of the PA

inputs to be somewhat low in drive, but the

inputs with shorted transistors would be

very low in drive.

NOTE

Insure that the REMOTE/LOCAL switch

located on the Controller board is in the

LOCAL position before performing the

checks outlined below. When the switch

is in the REMOTE position, RF Drive

and PDM are muted until the high volt-

age is turned on. After performing these

checks, set the switch back in the RE-

MOTE position.

It is usually advisable to check the RF

drive amplitude on the module before turn-

ing on the high voltage. It is not usually

necessary to readjust the IPA tuning.

RF Drive level is measured on the PA

modules with an oscilloscope. Place the

oscilloscope probe across R13 or the

equivalent terminal of any PA module. The

probe tip connects to the side closest to the

PA transistors.

Attach the probe ground lead to the RF

drive ground plane, which is the end of R13

furthest from the transistors. Do not use the

cabinet or chassis ground as this will give

an incorrect waveform. Proper drive level

should be 26-32 volts peak to peak on all

eight inputs of each PA module A1, A2, A3,

and A4, with the high voltage OFF.

C.8.

RF Drive Phasing Measurement

NOTE

Ensure that the REMOTE/LOCAL switch

located on the Controller board is set to

the LOCAL position before performing

the checks outlined below.

The RF drive phasing measurement may

be useful in locating some problems which

may be obscure to other means of trou-

bleshooting. Repeated failures of a particu-

lar PA transistor set might be caused by a

large drive phasing imbalance. Drive phase

imbalance could also reduce PA efficiency.

Measurements of the RF drive are made

with the transmitter in the OFF mode, but

the low voltage supply should be energized.

This is the usual condition when the trans-

mitter is ready to be turned on.

For the following procedure, an oscillo-

scope which can be externally triggered will

be required. This will allow examination of

the phase relationship between drive signals

on the PA.

Connect an oscilloscope across R13 posi-

tion on a PA module, with the probe tip on

the end of R13 closest to the transistors.

(Depending on the frequency of the trans-

mitter R13 may or may not be installed,

Figure C-1. Outline of MOSFET

C-2

888-2314-001

Rev. AE: 03-05-2002

WARNING: Disconnect primary power prior to servicing.

Summary of Contents for Gates Five 994 9204 002

Page 4: ......

Page 6: ...iv 888 2314 001 Rev X WARNING Disconnect primary power prior to servicing...

Page 8: ...vi 888 2314 001 Rev X WARNING Disconnect primary power prior to servicing...

Page 28: ...2 12 888 2314 001 Rev AC 2 29 00 WARNING Disconnect primary power prior to servicing...

Page 76: ...C 6 888 2314 001 Rev AE 03 05 2002 WARNING Disconnect primary power prior to servicing...

Page 82: ...E 4 888 2314 001 Rev AE 03 05 2002 WARNING Disconnect primary power prior to servicing...

Page 88: ...F 6 888 2314 001 Rev AE 03 05 2002 WARNING Disconnect primary power prior to servicing...

Page 96: ...H 2 888 2314 001 Rev AA 8 18 1999 WARNING Disconnect primary power prior to servicing...

Page 104: ...K 2 888 2314 001 Rev AE 03 05 2002 WARNING Disconnect primary power prior to servicing...

Page 108: ...L 2 888 2314 001 WARNING Disconnect primary power prior to servicing...