LAH Series Manual

- 8 -

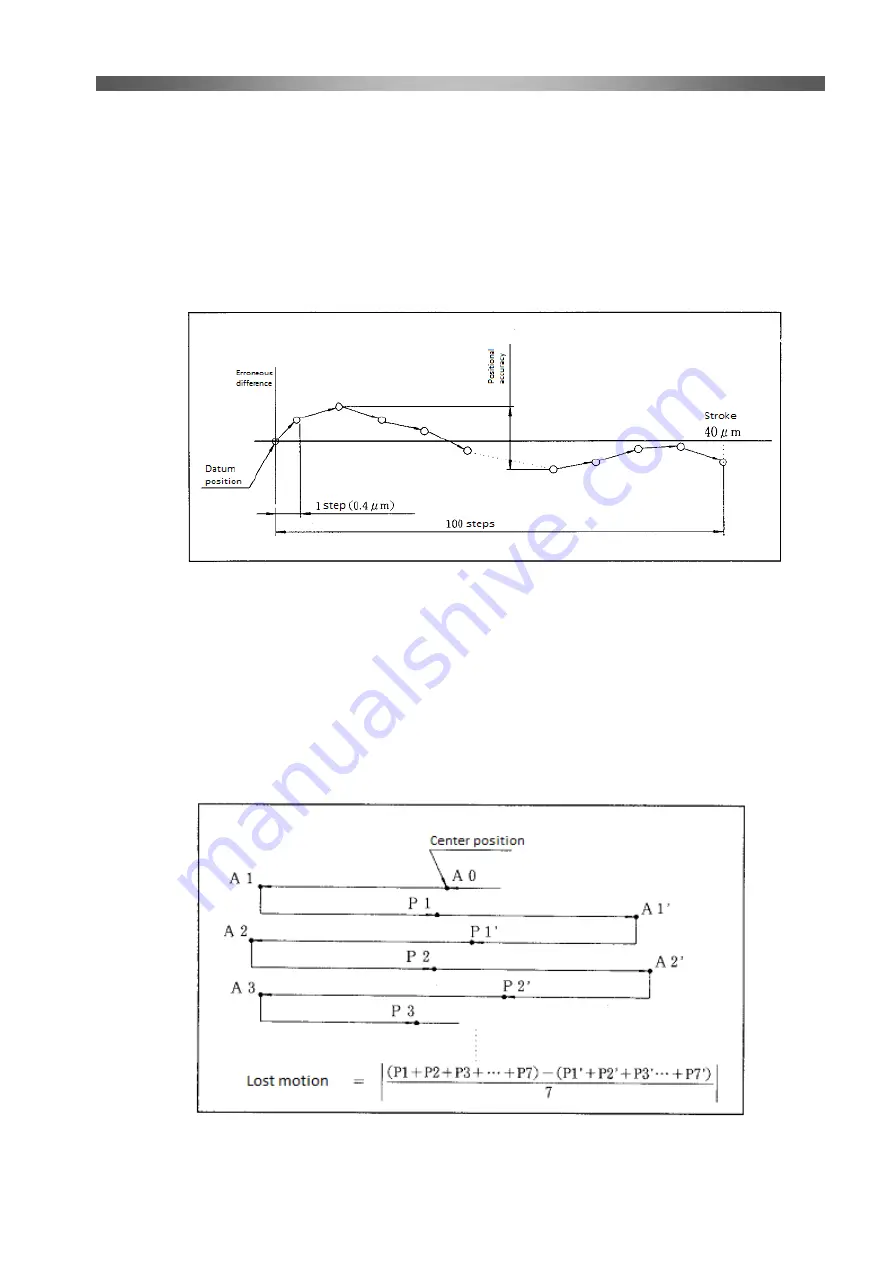

(3) Fine stroke positioning accuracy (See Fig. 7.)

a) Move the output rod in the pushing direction to the stroke center position. Mark that position as the datum

position.

b) From the datum position, perform sequential positioning for 100 p

oints (stroke 0.2mm) by feeding 2μm per step

in the pushing direction and measure each position.

c) At each position, the difference between the actual distance moved from the datum position and the distance to

be moved is considered as the erroneous difference. The greatest difference of the erroneous difference is the

positioning accuracy.

Fig.7

(4) Lost motion (See Fig. 8.)

a) Move the output rod in the pushing direction to the stroke center position. Mark that position as A0.

b) From A0, feed 1mm in the pushing direction. Mark that point as A1.

c) From point A1, feed 1mm in the pulling direction. Measure that point and mark it as P1.

d) From point P1, feed 1mm more in the pulling direction. Mark that point as A1'.

e) From point A1', feed 1mm in the pushing direction. Measure that point and mark it as P1'.

f) Repeat operations b) through e) 7 times. The difference between the average value of P1 through P7 and the

average value of P1' through P7' is the lost motion value.

Fig.8