44

1019658 11/2014

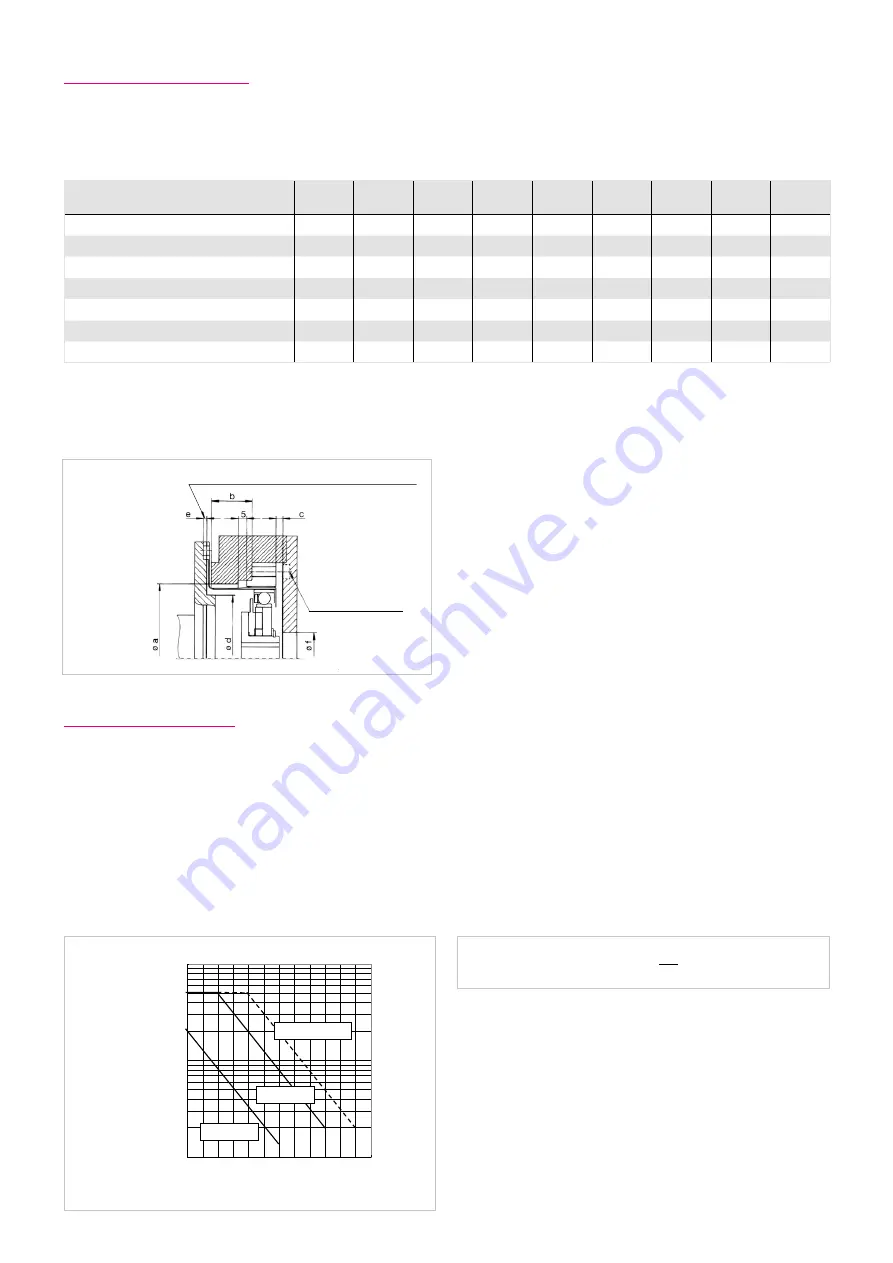

5.7.2 Grease Reservoir

For assembly please ensure that the grease reservoir is filled up with grease (dimension c and ø d in table 44.1 and

illustration 44.2).

Table 44.1

Illustration 44.2

Size

14

17

20

25

32

40

45

50

58

ø a

38

45

53

66

86

106

119

133

154

b

14.6

16.4

17.8

19.8

23.2

28.6

31.9

34.2

40.1

c*

1

1

1.5

1.5

1.5

2

2

2

2.5

c**

3

3

4.5

4.5

4.5

6

6

6

7.5

ø d

31

38

45

56

73

90

101

113

131

e

1.7

2.1

2

2

2

2

2.3

2.5

2.9

ø f

16

26

30

37

37

45

45

45

56

Maximum centering length

Countersink for

mounting bolt heads

* Horizontal and Vertical - Wave Generator below

** Vertical - Wave Generator above

5.7.3 Grease Change

To change the grease the component set should be completely disassembled and cleaned before regreasing. Fresh grease

should be applied generously to the inside of the Flexspline, the Wave Generator bearing, the Oldham coupling and the teeth

of the Circular Spline and Flexspline.

In illustration 44.3, the grease change interval depending on the grease temperature is given. The number of allowable revolu-

tions of the input shaft which represents the grease change interval can be estimated as shown in the example. This means,

that for a temperature of SK-1A or SK-2 grease of 40° C a change should take place after approx. 8.5 x 10

8

revolutions of the

input shaft. All grease change data refers to rated speed and rated torque.

Illustration 44.3

L

GT

= Number of Wave Generator revolutions until grease change

L

GTn

= see diagram

T

r

= Rated torque

T

av

= Average torque

L

GT

= L

GTn

.

(

)

3

T

r

T

av

Equation 44.4

1E+08

1E+09

1E+10

20

40

60

80

100

120

140

Grease Temperature [°C]

1E+10

1E+09

1E+08

Number of W

G r

evolutions

20 40 60 80 100 120 140

Flexolub A1

4B No. 2

SK1A, SK2