BATTER

Y

12 V

INSULATION

REMOVED FOR

CLARITY

OPEN

MOTOR

DEAD

NO LIGHT

0 V READING

BATTER

Y

12 V

INSULATION

REMOVED FOR

CLARITY

MOTOR

RUNS

LIGHTS UP

12 V READING

BATTER

Y

12 V

EXAGGERATED

TEAR OR CHAFF

MOTOR

DEAD

LIGHTS UP

12 V READING

BUT

( )

( )

BATTER

Y

12 V

INSULATION

REMOVED FOR

CLARITY

OPEN

MOTOR

DEAD

NO LIGHT

0 V READING

BATTER

Y

12 V

INSULATION

REMOVED FOR

CLARITY

MOTOR

RUNS

LIGHTS UP

12 V READING

BATTER

Y

12 V

EXAGGERATED

TEAR OR CHAFF

MOTOR

DEAD

LIGHTS UP

12 V READING

BUT

( )

( )

38

Section 2 : inStaller

Troubleshooting

troUBLeShootING

DeaLer oNLY SectIoN

The following procedures are reserved for the approved

installer/dealer. They should not be attempted by

anyone without proper knowledge of automotive

electrical circuitry.

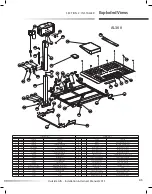

Be careful when troubleshooting with voltage meter.

The instruments will detect voltage but may not indicate

a tear or poor connection in the wiring.

It may give a false indication since it will only indicate

that there is some wire connection –not necessarily

enough.

[Figure 38-2]

It is strongly recommended that you examine both

voltage and current, or isolate sections of the lift wiring

using process of elimination with a known good/fully

charged 12V automotive battery or known good/fully

charged power chair/scooter battery.

ProBLem

• Lift does not operate.

• Lift operates slowly or intermittently

caUSe

Bad electrical connection(s) / Circuit

breaker

SoLUtIoN

Check / clean all connections that

might be loose or dirty. The lift

motor requires quality electrical

connections to operate at full

capacity; any break in the wiring

will slow down the motor and it will

deteriorate prematurely.

caUtIoN!

Be careful when troubleshooting

with a test light or voltage meter.

They may give false indications.

Figure 38-2

Inspect the full length of the wiring harness to

ensure the insulation is not torn. The lift’s vehicle

power harness running through or under the vehicle

is subject to road debris and rubbing against the

vehicle’s frame which can cause a short.

Verify the circuit breaker. The circuit breaker is located

about 6” from the connections to the vehicle’s battery.

The breaker will self-reset if overloaded; however,

verify (with Ohm meter or test light) that the breaker

is functioning. Or replace it with a new/known-good

circuit breaker and perform the following tests.

example of False Voltage reading

VOLTAGE

METER

AUTOMOTIVE

TEST LIGHT

Summary of Contents for AL010/050

Page 62: ...900 62 Notes ...