Summary of Contents for PF-100 Furnace

Page 14: ...Pellet Stove Service Training Installation Guidelines Harman Pellet Service Training 14 ...

Page 23: ...Harman Pellet Stoves Lighting and Operation Harman Pellet Service Training 23 ...

Page 30: ...Wiring Diagram applies to all automatic stoves Harman Pellet Service Training 30 ...

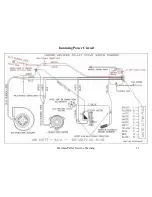

Page 31: ...Incoming Power Circuit Harman Pellet Service Training 31 ...

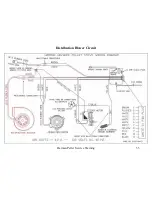

Page 32: ...Combustion Blower Circuit Harman Pellet Service Training 32 ...

Page 33: ...Distribution Blower Circuit Harman Pellet Service Training 33 ...

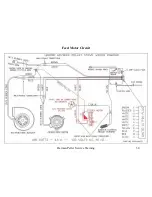

Page 34: ...Feed Motor Circuit Harman Pellet Service Training 34 ...

Page 35: ...Igniter Circuit Harman Pellet Service Training 35 ...

Page 36: ...PF 100 Wiring Diagram Harman Pellet Service Training 36 ...

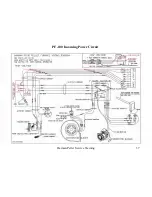

Page 37: ...PF 100 Incoming Power Circuit Harman Pellet Service Training 37 ...

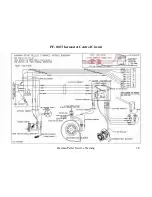

Page 38: ...PF 100 Thermostat Control Circuit Harman Pellet Service Training 38 ...

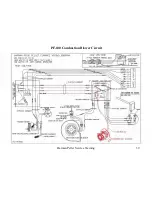

Page 39: ...PF 100 Combustion Blower Circuit Harman Pellet Service Training 39 ...

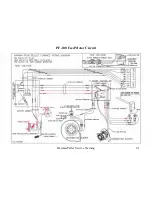

Page 40: ...PF 100 Distribution Blower Circuit Harman Pellet Service Training 40 ...

Page 41: ...PF 100 Feed Motor Circuit Harman Pellet Service Training 41 ...

Page 42: ...PF 100 Igniter Circuit Harman Pellet Service Training 42 ...

Page 48: ...Harman Pellet Stoves Cleaning and Maintenance Harman Pellet Service Training 48 ...

Page 50: ...Harman Pellet Stoves Technical Specifications Harman Pellet Service Training 50 ...

Page 56: ...The Harman Digital Diagnostic Meter Harman Pellet Service Training 56 ...

Page 58: ...Harman Pellet Service Training 58 PC 45 Burn Pots ...