Media-Mate Plus Operation Manual

25-710-800-O

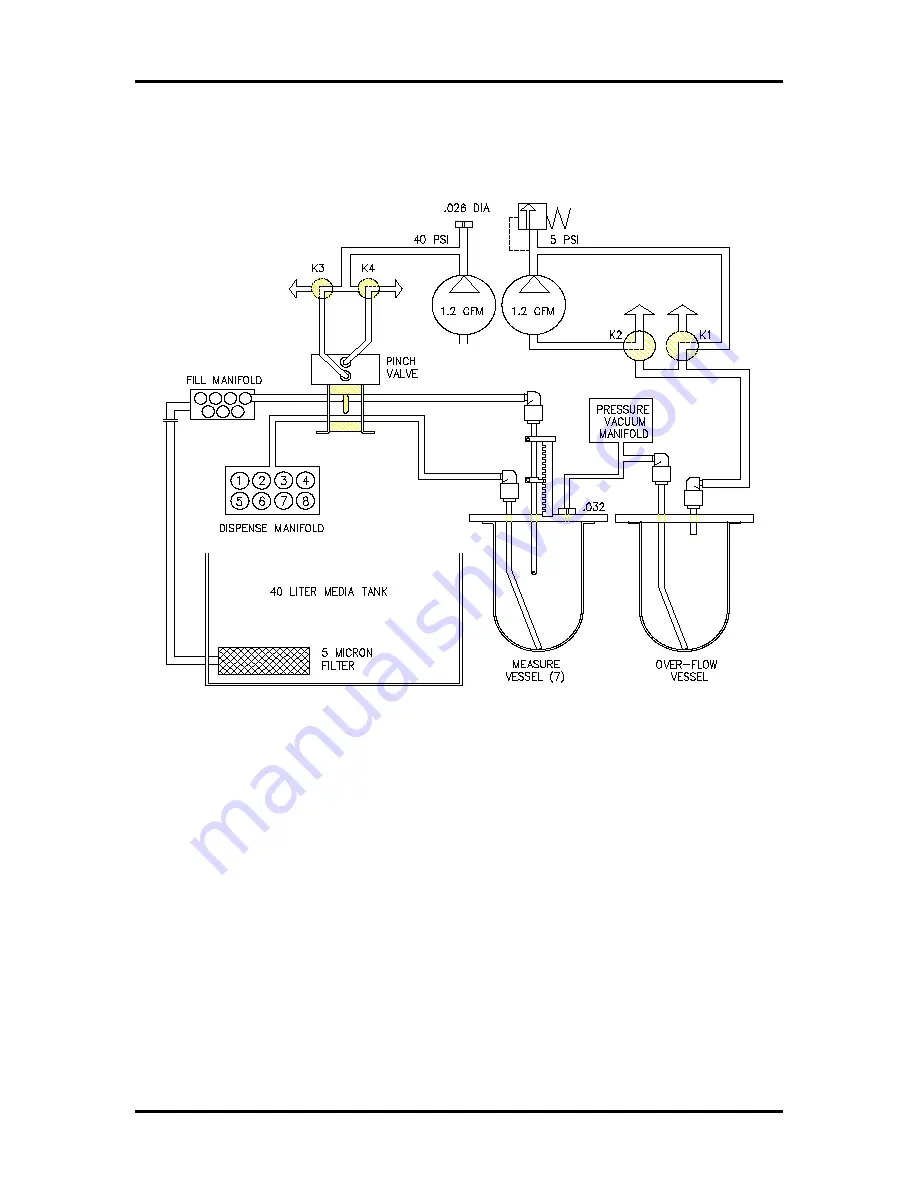

3. Dispense

(Dispense Light “ON”)

The pinch valve is shifted, opening the dispense lines and closing the fill lines. Pressure in the

measure vessels delivers media out the dispense manifold.

Figure 4-3

Section 4

How It Works

7