Remove unwanted sealing paste and apply paint

Procedure

1. Remove the sealing paste from all surfaces that are not contact surfaces.

2. Do a check for openings between the parts.

3. If you see openings, apply sealing paste and do steps 1 and 2 again.

4. Apply a protection on the oil seals of the gear unit to prevent them from

contamination.

5. Apply paint on all parts. Make sure that the paint agrees with the correct atmospheric

corrosion class. Refer to the order acknowledgement.

Install parts that give external loads to the gear unit

Note: Only do the steps if it is necessary to install parts that give external

loads on the gear unit.

Procedure

1. Make sure that the gear unit does not move during operation. Install thrust blocks.

2. Make sure that the distance between the external load and the housing of the gear

unit is as small as possible.

3. Make sure that only the external loads that agree with the order acknowledgement or

the certified drawing work on the gear unit. This includes the loads of the machine in

operation.

Install gear units with a backstop

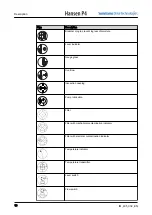

Warning:

• Do not loosen a part of the backstop when there is a load on the gear unit.

In this condition, the gear unit can turn in the incorrect direction.

• Make sure that a failure of a backstop cannot cause injury or damage to

the system.

• If the gear unit is used as a part of a system that moves persons, obey all

regulations and install all necessary safety devices.

Caution: Do not turn the gear unit in the incorrect direction. This condition

causes damage to the backstop.

Procedure

1. Make sure that the direction of rotation of the backstop shaft agrees with the direction

of rotation of the machine shaft.

Note: For drive groups, use a phase meter to do a check on the direction

of rotation of the machine shaft.

2. If it is necessary to change the direction of the backstop shaft, speak to H.I.T.

8.6

8.7

Installation

30

IM_405_002_EN