16

Step 5

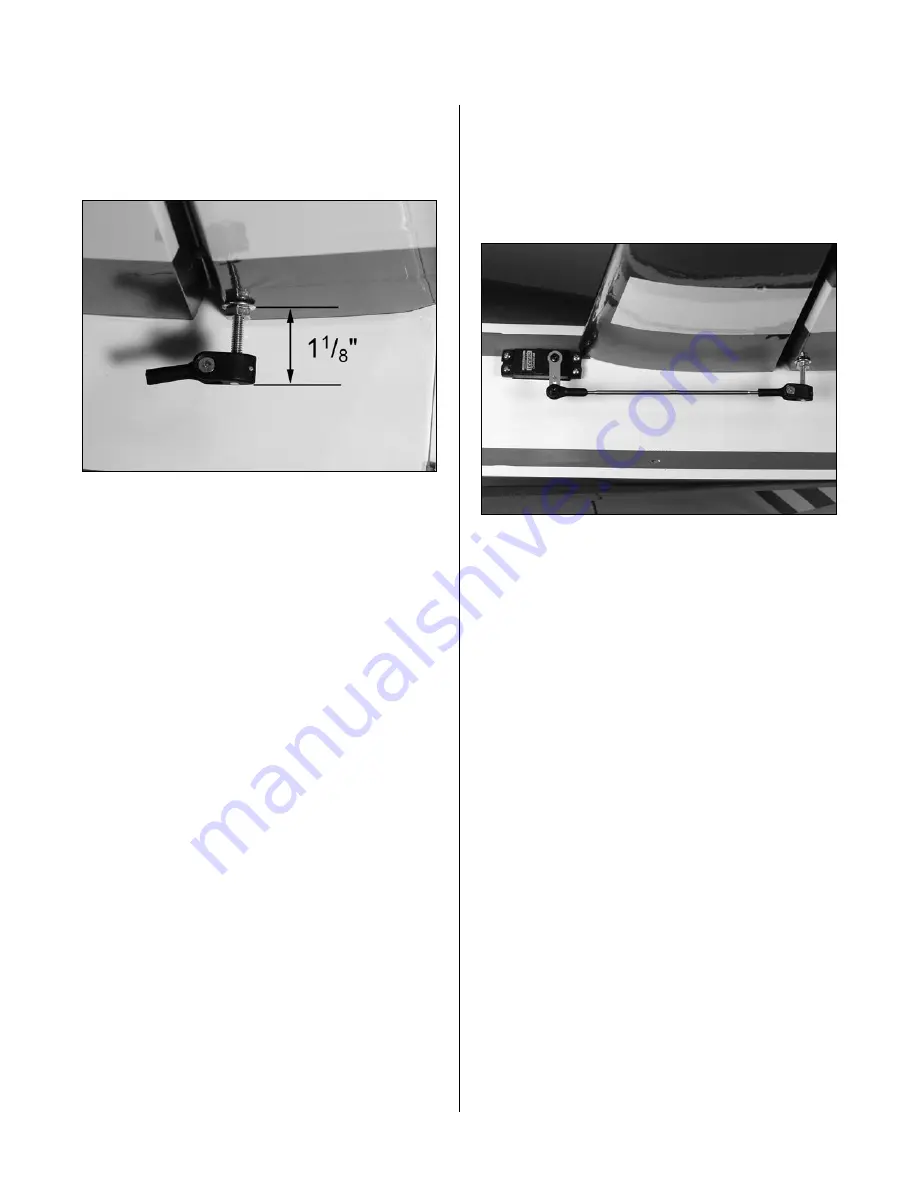

Screw the molded swivel link onto the 8-32 screw

until the distance from the elevator surface to the top

of the link is 1

1

/

8

".

Step 6

Remove the stock servo arms from the elevator

servos and replace them with 3D XL 1/2 servo arms.

The arms need to face down as shown. Be sure to use

a drop of threadlock on the servo arm screw if using

metal-geared servos.

Step 7

Screw a 4-40 ball link 5 to 6 turns onto a 5

1

/

2

"

elevator linkage. Screw the opposite end of the

linkage into the swivel control horn on the elevator.

Adjust the linkage length until the hole in the ball link

lines up with the outer hole in the servo arm when the

elevator is neutral and the servo arm is centered.

Step 8

Use the included 4-40 screws and nuts to attach

the ball link to the outer hole in the arm. From the

topside, the correct sequence is 4-40 screw, ball

link, servo arm and 4-40 locknut. Be sure to use

threadlock.

Step 9

Repeat Steps 1 through 8 for the remaining elevator

servo and linkage.

Section 5 – Elevator Servo Installation