16 Chuk/Changer Instruction

IMPORTANT NOTICE

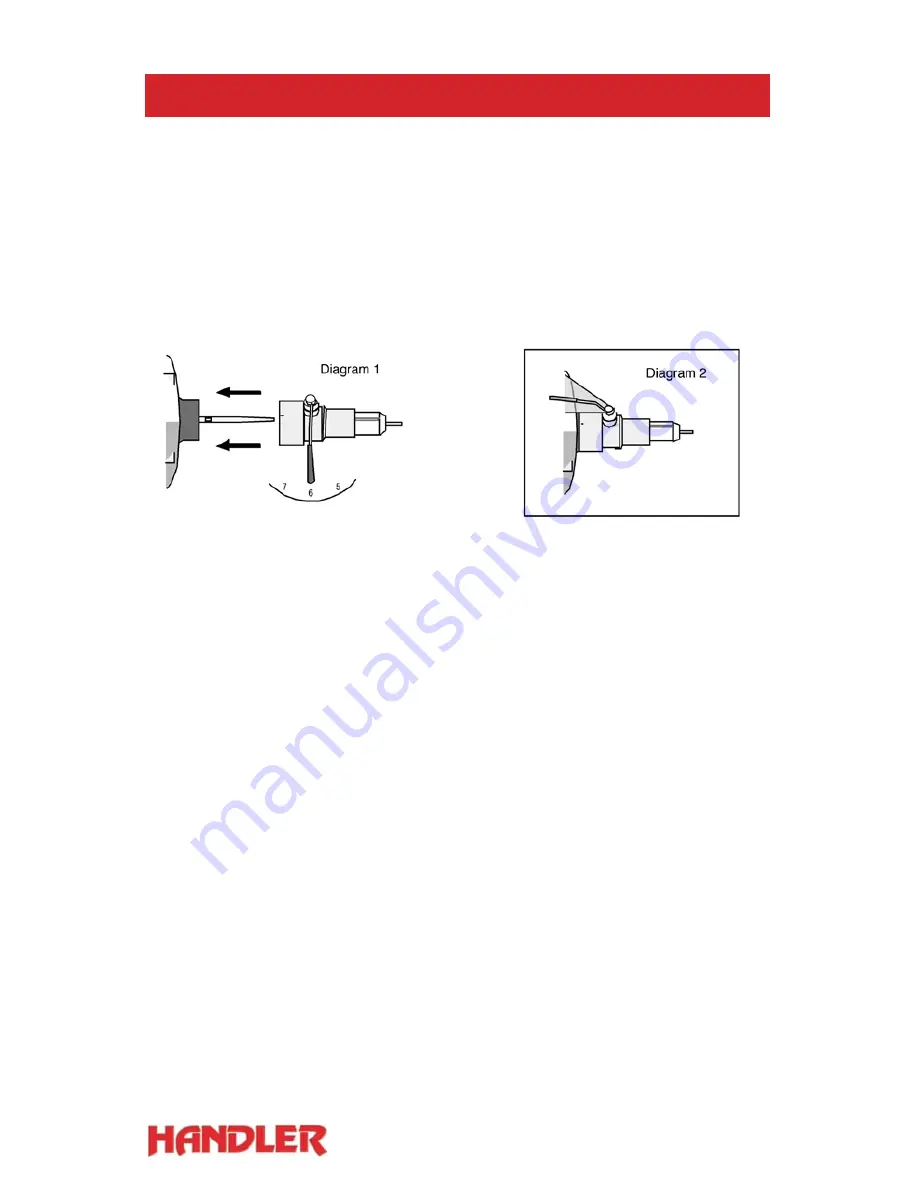

Adjusting Chuk/Changer to Tension Collets

The alignment of the Chuk/Changer to the clutch will alleviate slipping clutch noise prob-

lems and tension collets. Please follow the instructions, below, to alleviate these problems.

1. Remove the plug which connects the lathe from the electrical source.

2. Move the activating handle on the Chuk/Changer to the six o’clock (open collet)

position as seen in diagram 1.

3. Loosen the top set screw and the two lower set screws, which are found on the

2-1/2” adapter, which hold the Chuk/Changer onto the lathe.

4. Place your left hand on the left hand side of the lathe and your right hand on the

nose section of the Chuk/Changer, and push the Chuk/Changer in toward the lathe

as far as it will go. It will move approximately 1/32-1/16 of an inch inward toward

the lathe.

5. Holding the Chuk/Changer in your right hand, move the activating handle clockwise

to the 9:30- 10:00 o’clock position. The Chuk/Changer will move outward, slightly.

Tighten the three set screws on the adapter which were previously loosened, holding

the Chuk/Changer in position as seen in diagram 2.

NOTE:

If you have another person available to assist you in this short procedure,

ask them to tighten the set screws. If you do not, make certain that you hold the Chuk/

Changer inward toward the lathe when you tighten the set screws on the adapter.

This should alleviate the squeaking-grinding noise you are hearing by the lathe Chuk/

Changer combination and place proper tension on collets.

REMEMBER:

Clean collets every 30 days.

Your Chuk/Changer has been manufactured, assembled, adjusted and tested with the

utmost of care to insure that you will receive it in perfect condition. We ask that you

carefully read and follow these step by step instructions.