HAMWORTHY HEATING LTD

84

Merley Boiler Sequence Controller

500001210/D

7 Plant diagrams

The various applications are shown in the form of basic diagrams and extra functions.

The basic diagrams show possible applications that can be implemented without the use

of multifunctional outputs.

7.1 Basic diagrams

The basic diagrams are examples of plant that can be implemented with standard out-

puts requiring only a few settings.

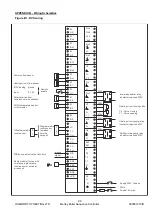

Diagram

Function

Q1

Boiler pump

Q2

1st heating circuit pump

Q3

DHW charging pump / diverting valve

Q4

circulating pump

Q14

System pump

Q15

H1 pump

Q25

Cascade pump

Q33

DHW intermediate circuit pump

Y1

1st Heating circuit mixing valve

Y4

Heat source shutoff valve

Y7

Maintained boiler return temperature

Y19

Primary controller

Y31

DHW primary controller mixing valve opening

Y32

DHW primary controller mixing valve closing

K6

Electric immersion heater

Legend mains voltage

Legend low

-

voltage

B1

Flow temperature sensor HK1

B12

Flow temperature sensor HK2

B2

Boiler temperature sensor TK1

B3

DHW sensor top

B31

2nd DHW sensor bottom

B35

DHW flow temperature sensor

B36

DHW charging sensor

B38

DHW temperature outlet sensor

B15

Flow sensor primary controller

B39

DHW circulation sensor B39

B7

Return sensor

B70

Cascade return sensor

B73

Primary circuit return sensor

B9

Outside sensor.

B10

Common flow sensor

RG1

Room unit 1

FS

Flow switch