7.4. Checking the combustion circuit seal

Check for leaks with a foaming product. The areas

to be checked are shown in the figure opposite.

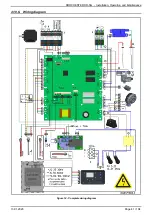

The check should be carried out when the appliance

is cold (water heater turned off) but with the fan at

maximum speed (obtained by disconnecting the

PWM signal connector - see electrical diagram).

If you detect any leaks, you must replace the seal

with the adapted kit.

We recommend replacing the seals each time it

is opened.

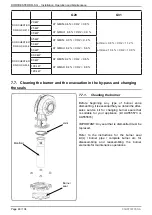

7.5. Checking the combustion quality

This check is carried out with a calibrated

combustion kit. To do so, insert the measurement

rod into the fume nozzle (see figure opposite).

The water heater setpoint must be equal to or

greater than 65°C.

IMPORTANT:

Do not forget to put the cap back on the sampling plug opening after

the measurement.

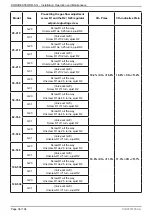

The CO

2

content measured under these conditions must be within the

values indicated in the table on the end of section 7.6 (depending on

the type of gas and the Dorchester DR-SG model).

If this is not the case, you must readjust the gas valve (see next §).

Following this check, you must take a "gas start" flow rate measurement. This

measurement is used to check the dirt build-up on the combustion circuit.

The "gas start" must be made for a period over 3 minutes to obtain a

satisfactory level of accuracy.

If the gas flow rate is 20% lower in relation to the value indicated in the table

in paragraph § 3.3, you must clean the burner (see § 7.7).

figure 20 - Sampling plug

Fume sampling plug

opening

figure 19 - Combustion leaks

Zone to be

checked

Page 46 / 104

00U07337760-A

DORCHESTER DR-SG -

Installation, Operation and Maintenance