11

TROUBLESHOOTING

If the Vacuum Sealer does not operate when it is plugged

in and turned on, try any or all of the following:

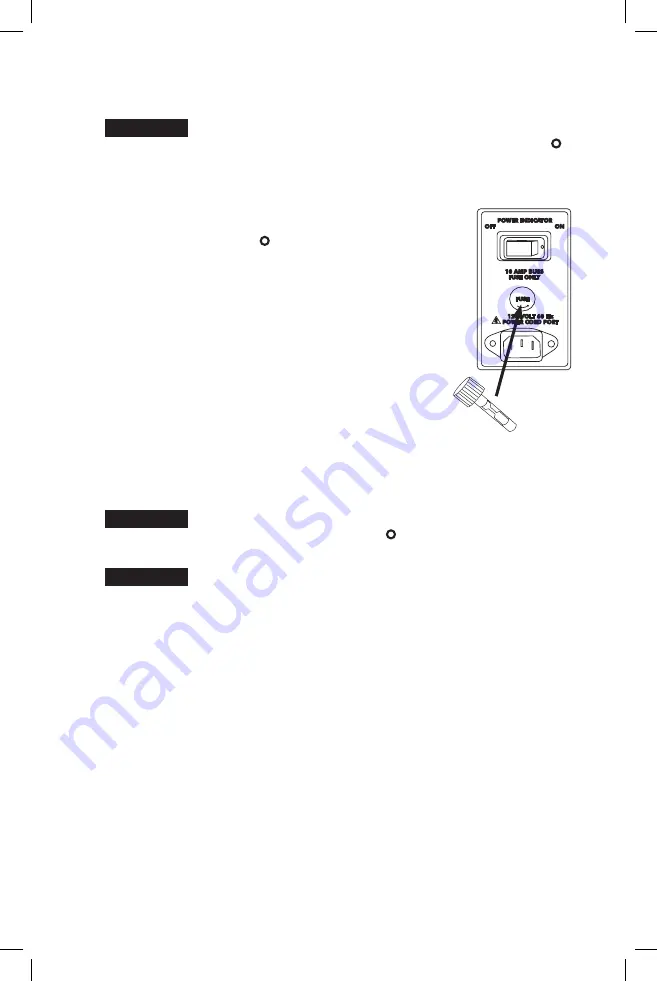

1. Make sure the Fuse is not blown. The Fuse is located

on the right side of the unit directly above the Power

Cord Port. Turn “OFF” ( ) and unplug the Vacuum

Sealer. Twist off and remove the Fuse Cap. Remove

and check the Fuse. The thin metal band in the

center of the Fuse should be clean and unbroken.

Only replace fuse with a 10-ampere cartridge fuse.

Replace the Fuse Cap.

2. Make sure the Connector at the end of the Power

Cord is plugged completely into the Power Cord Port.

3. Make sure the Power Cord is not damaged. DO NOT

use a damaged Power Cord. Call Customer Service

for information on part replacement.

4. Try connecting the Power Cord Plug to another

electrical outlet.

CLEANING INSTRUCTIONS

•

NEVER IMMERSE the Vacuum Sealer in water or other liquid.

•

Wipe all outside surfaces including the plastic Vacuum Chamber and

Vacuum Lid with a damp cloth or paper towel. Avoid spraying cleaner or

any other liquid directly into the vent on the left side of the unit. DO NOT

use abrasive cleansers! Abrasive cleansers will spoil the clarity of the

Vacuum Lid.

•

Avoid peeling or damaging the Seal Bar Tapes.

•

Dry all surfaces and close the Vacuum Lid before storing the Vacuum

Sealer.

w

WARNING

Electrical Shock Hazard.

Before cleaning the Vacuum

Sealer, make sure the Vacuum Sealer is OFF ( ) and the plug is removed from

the outlet/power source.

w

WARNING

Electrical Shock Hazard.

Before assembling or

disassembling the Vacuum Sealer, make sure the Vacuum Sealer is OFF ( )

and the plug is removed from the outlet/power source.

w

CAUTION

Burn Hazard.

The Seal Bar and Vacuum Chamber Seal get hot

and can cause burns. Avoid contact. Allow Vacuum Sealer to cool for 20 minutes

before cleaning.

Summary of Contents for HVS400

Page 21: ...21 NOTES...

Page 31: ...31 NOTAS...