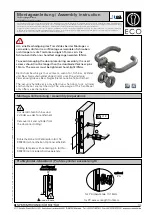

Figure 7: Lid Assembly

To refit the Lid assembly;

1.

Place Lid Assembly onto the Solenoid Switch enclosure.

Note: No additional sealing elements or compounds (for example Silicon sealant) are required to refit and reseal the

Lid Assembly. Any additional materials or work may reduce IP level and will void Fortress warranty.

2.

Refit and tighten the 10 x M8 Torx screws in an even distribution. For example;

i. Half tighten screws in the order specified in Figure 7.

ii. Fully tighten screws in the order specified in Figure 7.

iii. Check and, if necessary, re-tighten screws in the order specified in Fix.2.

Note:

All M8 Torx lid screws must be fully refitted and tightened to a minimum torque setting of 20Nm to maintain IP

level. Note: It is recommended that all M8 Torx Lid screws be secured against tampering removal or loosening due to

vibration using a middle strength adhesive threadlocker.

3.

Fully test and operate the complete Alfred Solenoid Controlled Guard Lock to ensure correct function and operation. See

Mechanical Function Test section for more details.

If required, any replacement Lid assembly screws must be identical to those as supplied by Fortress and must be M8 x

14mm, property class of A2-70 with a minimum yield strength of 700 MPa to ISO 3506, ISO 262, ISO 965-1, and ISO 965-3.

FORTRESS

A company

Halma

www.fortressinterlocks.com

THE COPYRIGHT OF THIS DRAWING BELONGS TO FORTRESS INTERLOCKS Ltd.

THE CONTENT OF THIS DRAWING IS CONFIDENTIAL AND MUST NOT BE

DISCLOSED TO ANY 3rd PARTY WITHOUT SPECIFIC, WRITTEN APPROVAL.

ALL DIMENSIONS

ARE IN mm UNLESS

OTHERWISE STATED

A3

SCALE:

0.50

SHEET:

2 OF 3

ORIGINAL SIZE

DATE:

25-02-21

ISSUE:

0

ALFRED SAFETY SWITCH OPERATING INSTRUCTIONS IMAGES

DWG NO:

SD-00033

Operating Instructions: Alfred Solenoid Controlled Guard Lock

15

Electrical Connection and Installation

Tools and Fixings Required

Terminal Screwdriver.

Cable and Wiring selection requirements:

• All cabling and wiring used to connect and install the Alfred Solenoid Controlled Guard Lock must be of an equal or greater

level of ATEX and IECEx protection in order to maintain ATEX Device ratings (See ATEX, IECEx and HazLoc section for

Device rating and detail).

• Correctly rated and sized cable glands and connectors must be used in order to maintain the IP67 and IP69 protection

rating of the Ex Rated Solenoid module.

Note:

The conduit connection hole of the Solenoid Module is an M20 x 1.5mm pitch threaded hole.

• The cable and cable gland used must have a minimum service temperature in excess of 70˚C.

• The wire used to connect to the Internal Earthing point of the Solenoid Module (see Figure 11) must have a greater than or

equal cross-sectional area to that of the phase conductor wires.

Note:

The internal Earthing point shall be used for the Equipment Grounding connection.

• The wire or cabling used to connect to the External Earthing point of the Solenoid Module (see Figure 11) must have a

cross-sectional area of at least 4mm2.

Note:

The external Earthing point shall be used for a Supplementary Bonding Connection where local codes or authorities

permit or require such connection.

• Both the Internal and External Earthing wires must be secured and clamped so that they cannot be readily loosened or

twisted. This could be done using a U-Shaped Saddle Clamp or similar.

• All internal wiring for the Safety Circuits and Gate Monitor Circuits must be made using 24-16 AWG copper cable.

SWITCH ENCLOSURE

LID ASSEMBLY

M8 TORX LID SCREWS