18

MiniCAFS 2.1A Operating Manual

GP/211/05 Issue 2. April 2005

©Hale Products Europe. Our policy is one of continuous development. We therefore

reserve the right to amend specifications without notice or obligation.

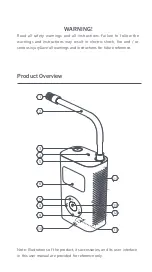

Wet Foam or Dry Foam

2.4. A continuously variable foam type from WET to DRY is available, selectable by the

pump operator.

2.5. The WET or DRY foam composition is selected by using the WET/DRY control on the

panel (No.1 Page 7). An indication of foam type is given by the WET or DRY foam

indicator (No.7 Page 7), but the pump operator may choose to optimise the liquid flow

as displayed in the FoamLogix display.

2.6. To increase the WET or DRY property of the foam, press the WET/DRY control

(No.1) at the top for WET or the bottom for DRY.

2.7. Note: when discharging dry foam at low pump pressure, the possibility of hose

kinking is increased and should be considered when deploying hoses on the fire

ground.

Note: the WET/DRY value will always default to wet when the compressor is stopped.

Shutting Down

2.8. Set WET/DRY selector switch to the WET foam setting (Press in

bottom

of switch)

2.9. Turn off the FoamLogix, press RED button.

2.10. Run water through the CAFS discharge system to flush out the foam agent.

2.11. Close the CAFS discharge valves

2.12. Switch off the engine.

2.13. If cold weather is expected, open the drain taps

(K, Page 12)

to drain the CAFS

manifold.

Overheat Shut down

If the compressor is running hot, a warning indicator light will illuminate on the control panel

when oil temperature reaches 105

o

C.

If the compressor oil temperature exceeds 110º C, the unit will shut down automatically. The

compressor can sustain 105ºC temperatures for short periods without damage. The unit can

be re-started when the compressor has cooled.

The most likely cause of compressor overheat problems is insufficient cooling water flow.

Verify that the cooling water return line is not kinked or restricted before running again.

Cooling water flow is approximately 40l/min minimum.

Note

: The system is designed to allow the air pressure to decay slowly which

reduces the tendency of the oil to froth when releasing the entrained air.