Bias

Remove the B +

fuse F2. This fuse is in the line from the

’ +’

c a p a c i t o r

terminal to hole # 3 on the board. Connect an

ammeter’s

'

+

'

!ead to the fuse clip nearest the large filter

capacitors. Connect the’

-’

lead to the other side of the fuse clip.

Avoid intermittent connections, and do not short the leads

together. Turn the amplifier on, and if possible adjust the line

voltage to 120 volts. Adjust P2, near the middle of the board, to

275 mA. Turn the amplifier off, and when the current drops to

zero, then remove the ammeter and replace the fuse.

Offset

A DC voltmeter capable of resolving 10 mV variations is

needed. Connect it to the output terminals of the selected chan-

nel, and adjust Pl, near the top of the board, to zero volts, + 10

mV. A small correction of the control will produce a large initial

change, which will settle

down

in a second. Repeat these small

changes to achieve zero volts.

SERVICE POLICY AND LIMITED WARRANTY

The DH-220 Power Amplifier has been carefully engineered

to provide many years of use without requiring any mainte-

nance or servicing.

Factory assembled units are subjected to several physical and

electrical tests before shipment. The output circuit board

assemblies of kit units are similarly tested prior to shipment. In

spite of all this testing,shipping damage does occur, kits are not

assembled properly or someone “goofs” and service and/or

maintenance will be required. The David Hafler Co. provides

complete service facilities at the factory to make any necessary

repairs.

It is the owner’s responsibility

to return or ship the unit freight

prepaid to the factory service department. Units shipped freight

collect will not be accepted. For units to be repaired under war-

ranty a copy of the dated bill of sale must accompany the unit.

Shipment should be via UNITED PARCEL SERVICE. Parcel

Post is not a safe way to ship electronic equipment. The factory

will not be responsible for damage caused by parcel post ship-

ment and repairs will be made at the owner’s expense. When

shipping your DH-220 be sure to insure it for the full value of an

assembled amplifier.

Use the original carton and packing material to ship your

amplifier. Enclose with the unit the following information:

1.

2.

3.

4.

5.

Complete shipping address (Post Office Box numbers are

often n o t acceptable.)

The serial number.

Copy of dated bill of sale if repairs are to be made under war-

ranty.

Description of the malfunction. If intermittent, please note.

We also suggest further identifying the unit as yours by put-

ting a label on the bottom or tieing a label with your name

and address on the line cord.

All service work is guaranteed for 90 days.

Warranties apply to the original purchaser only. Warranties

are void if: a) the amplifier has been either physically or elec-

trically abused or used for some purpose for which it was not

designed, or b) the amplifier has been modified without factory

authorization.

The transformer warranty is void if the leads have been cut

too short for reuse. If you think a transformer is defective the

leads must be unsoldered, not cut, for its return.

Technical assistance to help you locate the source of a prob-

lem may be obtained by calling the Technical Services Depart-

ment at 609-662-6084, 8 a.m.-4:30 p.m. E.T. It is helpful to

know the serial number of the unit and the results of any tests

you have performed.

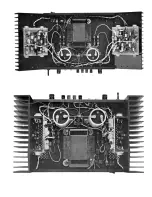

SERVICING AN AMPLIFIER MODULE

If you are certain that the problem is confined to one of the

amplifier modules (comprising the circuit board, heat sink, and

output transistors), you may remove and return only the

module for service. Be sure that the components on the circuit

board are well protected - as by a surrounding sleeve of cor-

rugated cardboard which rests against the heat sink, and pro-

jects beyond the components. Properly packed and insured for

$150, this assembly can be sent by parcel post, as well as UPS, if

necessary. A service fee of $20 must be sent with every module,

since the fault may have been caused by a wiring error

elsewhere. For this reason, too, and because we have no control

over its proper reinstallation, the service warranty on a separate

module is limited to assurance of its proper functioning when it

leaves the service facility. All modules are tested before being

returned to you. If you believe the fault is the factory’s warranty

responsibility, include the serial number and the

bill of sale.

If in

our judgement the fault is entirely a manufacturing defect, a

portion of the service fee will be refunded. Only a complete

amplifier can be fully checked and given a service warranty.

WARRANTY FOR KIT-BUILT UNITS

The parts in a DH-220 kit are warranted for a full year from

the purchase date. If a defective component is found on a circuit

board or in a kit, simply return the

individual

part to the factory

prepaid together with the serial number and the date of pur-

chase, and it will be replaced at no charge.

If you cannot locate what is wrong with your DH-220, return it

to the factory with a copy of the dated bill of sale, and a check for

$40. If the sole cause of the problem is a defective part, the unit

will be repaired and returned to you transportation prepaid, and

your $40

less a charge for repackaging and shipping

will be

returned to you. If the problem is found to be an error in your

assembly of the amplifier, the amplifier will be put in proper

working order, tested to be sure it is meeting specifications, and

returned to you (freight prepaid within the continental U.S.). Ex-

cess shipping charges for expedited service, or overseas

delivery are your responsibility. At the sole discretion of the fac-

tory service department, if the time required for diagnosis,

repair and testing, and the nature of the malfunction warrants it,

a portion of the submitted repair fee may be rebated.

This warranty is void if the kit has not been completely

assembled or if other than rosin core solder has been used. Units

assembled with acid core solder or paste flux will be returned

unserviced.

WARRANTY FOR FACTORY ASSEMBLED UNITS

The DH-220 is warranted for three years from the purchase

date including parts and labor and normal shipping costs from

the factory to the owner within the continental U.S. The owner

is responsible for returning the unit to the factory and must sub-

mit a copy of the dated bill of sale.

This warranty gives you specific legal rights. You

have other rights which vary from state to state.

may also

11