15

F. OPERATION

After assembling the machine, remove the anti-corrosion coating on the slideway, carriage,

toolpost, tailstock and change gears with a clean cloth and kerosene. Once the machine is

clean lubricate the machine as per instructions.

19

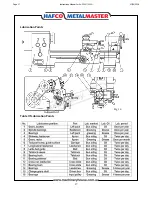

F.1 Illustration Of The Operation Parts

1. Socket head cap screw: to open or close the cover of the gear change box

2. Plug: the power lead and plug of the machine

3. Shifting handle: has three positions to adjust the speed.

4. For/Rev handle: has three positions which changes the direction of the tooling travel.

The middle position is neutral.

5. Shifting handle: Has two positions to adjust the speed.

6. Forward/reverse switch: to control the rotation directions of the motor and spindle. It can

be operated only after the motor is stopped.

7 Start button: to start the motor

8. Stop button: to stop the motor

9. Longitudinal hand wheel: to operate the apron longitudinal movement

10. Cross hand wheel: to move the cross slide and toolpost.

11. Toolpost handle for loosing or locking the toolpost

12. Nuts: to fix the top slide to the cross slide. This can allow rotation on the topslide.

14. Toolpost hand wheel: to move the topslide and toolpost forward or backward

15. Handle: to control the half-nut for threading

16. Handle: to control the longitudinal and cross auto feeding which has three positions.

18. Lever: to lock the tailstock. The tailstock can be removed or moved freely after loosening.

17. Tailstock Sleeve lock lever. Locks the sleeve in place after moving

19. Tailstock hand wheel: moves the sleeve after the lock lever is loosened.

20. Screw: to adjust the centering position of the tailstock, with the main spindle. Can be

adjusted for taper turning

Page 15

Instructions Manual for AL-320G (L141)

07/02/2018

Summary of Contents for AL-320G

Page 10: ...10 Thread Chart Page 10 Instructions Manual for AL 320G L141 07 02 2018 ...

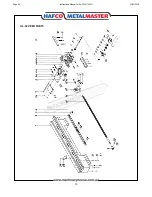

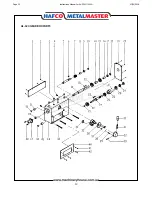

Page 20: ...20 AL 320 BED PARTS Page 20 Instructions Manual for AL 320G L141 07 02 2018 ...

Page 23: ...23 AL 320 HEADSTOCK PARTS Page 23 Instructions Manual for AL 320G L141 07 02 2018 ...

Page 27: ...27 AL 320 BACK GEARS PARTS Page 27 Instructions Manual for AL 320G L141 07 02 2018 ...

Page 30: ...30 AL 320 GEARBOX PARTS Page 30 Instructions Manual for AL 320G L141 07 02 2018 ...

Page 33: ...33 AL 320 APRON PARTS Page 33 Instructions Manual for AL 320G L141 07 02 2018 ...

Page 36: ...36 AL 320 COMPOUND SLIDE PARTS Page 36 Instructions Manual for AL 320G L141 07 02 2018 ...

Page 38: ...38 AL 320 TAILSTOCK PARTS Page 38 Instructions Manual for AL 320G L141 07 02 2018 ...