23

OPERATION MANUAL

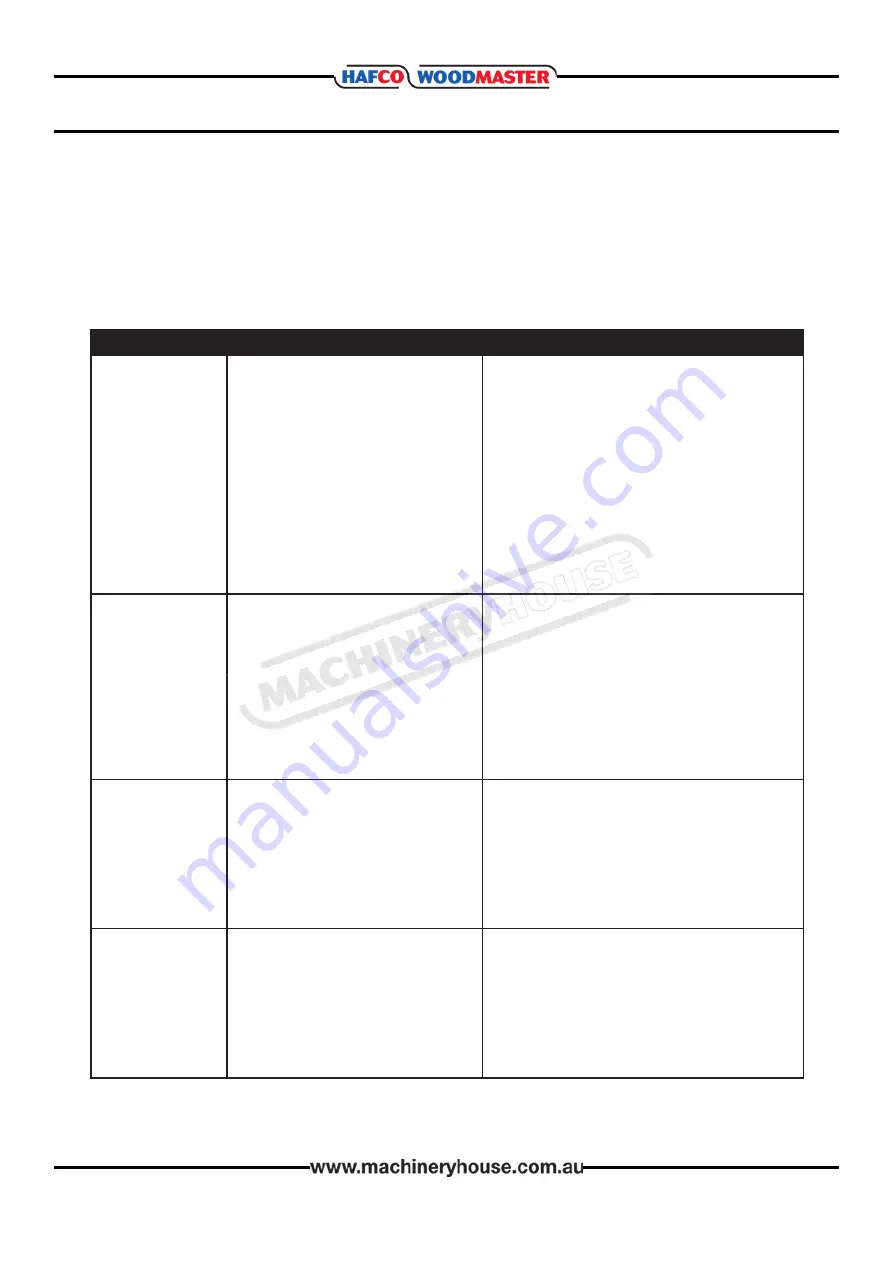

5.3 TROUBLESHOOTING

SYMPTOM

SYMPTOM

POSSIBLE CAUSE

POSSIBLE SOLUTION

Machine does not

start or a breaker

trips.

1. Stop push-button engaged/faulty.

2. Power switched OFF or at fault.

3. Thermal overload relay has tripped.

4. Wall circuit breaker tripped.

5. Plug/receptacle at fault/wired

incorrectly.

6. Motor connection wired incorrectly.

7. Contactor not energized.

8. Wiring open/has high resistance.

9. ON/OFF switch at fault.

10. Start capacitor at fault.

11. Centrifugal switch at fault

12. Motor at fault.

1. Check magnetic switch/replace it.

2. Ensure power supply is switched ON

3. Reset trip load dial if necessary; replace.

4. Ensure circuit size is correct/replace.

5. Test for good contacts; correct the wiring.

6. Correct motor wiring connections

7. Test all legs for power/replace if faulty.

8. Check and fix broken, disconnected wires

9. Replace switch.

10. Test/replace if faulty.

11. Adjust/replace centrifugal switch.

12. Test/repair/replace.

Machine stalls or is

underpowered

1. Feed rate too fast.

2. Workpiece material not suitable.

3. Dust collection ducting problem.

4. Motor overheated.

5. V-belt(s) slipping.

6. Run capacitor at fault.

7. Pulley/sprocket slipping on shaft.

8. Motor bearings at fault.

9. Motor at fault.

1. Decrease feed rate.

2. Ensure timber moisture is below 20%.

3. Clear blockages, use smooth wall duct,

4. Clean motor, let cool, and reduce load.

5. Tension/replace belt(s) ensure pulleys

are aligned

6. Test/repair/replace.

7. Replace loose pulley/shaft.

8. Test/repair/replace.

9. Test/repair/replace.

Excessive step

(snipe)

(gouge at the end

of the workpiece

that is uneven with

the rest of the cut).

1. One or both of the bed rollers are

set too high.

2. Rear table extension slopes down or

is not level with the table

3. Chip breaker or pressure bar set too

low

4. Workpiece is not fully supported as it

leaves the thicknesser.

1. Lower the bed rollers

2. Adjust the rear extension wing set screws

to make the extension level with the table

3. Raise the height of the chip breaker or

pressure bar

4. Use a roller stands to properly support the

workpiece as it leaves the thicknesser.

Workpiece stops/

slows in the middle

of the cut.

1. Depth of cut too deep.

2. Pitch/glue build-up on thicknesser

components.

3. One or both of the bed rollers are set

too low or too high.

4. Chip breaker or pressure bar set too

low

5. Feed rollers set too low or too high.

1. Reduce the depth of cut.

2. Clean planer components with a pitch/

resin dissolving solvent.

3. Lower/raise the bed rollers

4. Raise the height of the chip breaker or

pressure bar

5. Adjust the feed rollers to the correct height

Should any problems arise review the troubleshooting procedures in this section to find the

possible problem or fix and adjust your machine.

The spare parts view and the proceedure for ordering is layed out in the spare parts section.