15

OPERATION MANUAL

3.5 TEST RUN

Once the assembly is complete, test run your machine to make sure it runs properly and is

ready for regular operation.

The test run consists of verifying that the motor powers up and the machine runs correctly.

When operating correctly, the machine runs smoothly with little or no vibration or rubbing

noises. If, during the test run, you cannot easily locate the source of unusual noise or vibration,

stop using the machine immediately, then review the Troubleshooting section on Page 23.

If you still cannot remedy a problem, contact your distributor

4. OPERATION

4.1 BASIC CONTROLS.

The following descriptions will help you to become

familiar with the basic controls of your machine.

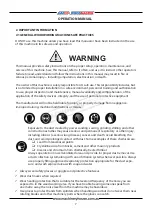

ON/OFF Switch:

Starts/stops the spindle and the

drive rollers of the Thicknesser. (Fig. 4.1)

Overload Reset Button:

This machine has a motor

thermal overload protection switch, which will trip if

the motor becomes too hot. To reset the switch, move

the ON/OFF switch to OFF, wait a few minutes to allow

the motor to cool, then press the reset button.

F

ig

. 4.1

on/oFF b

utton

r

eset

b

utton

Height Adjustment Handle:

The thicknesser depth of

cut is controlled by using the elevation crank on top of

the machine. Rotating the crank clockwise raises the

cutterhead. (Fig. 4.2)

F

ig

. 4.2

h

eight

aDjustment

Depth of Cut Scale:

The Depth Of Cut Scale, located

on the front of the machine, is a convenient way to

quickly determine how much material is being planed

off in one pass. (Fig. 4.3)

1. With the machine OFF, insert your workpiece just

under the depth of cut scale

2. Crank the raising / lowering handle until the button

(B) comes in contact with the workpiece.

3. As you rotate the raising / lowering handle, the

needle on the depth of cut scale will move showing

you how much material will be removed in that

pass under the depth of cut scale.

NOTE: The manual depth gauge can be reset by

adjusting the three fixing screws that hold the gauge to

the machine.

F

ig

. 4.3

A

B