78

Maintenance

9.4.2 Working with Wiring Connectors

All inter-connect wiring plugs and receptacles are mechanically polarized to assist in proper

insertion. Always note where a connector belongs and what orientation it was in prior to removal.

This will assure that you get it back in the right place during reassembly.

Locations and descriptions of each fuse and connector on the Base Board and CPU

board are shown in

and

.

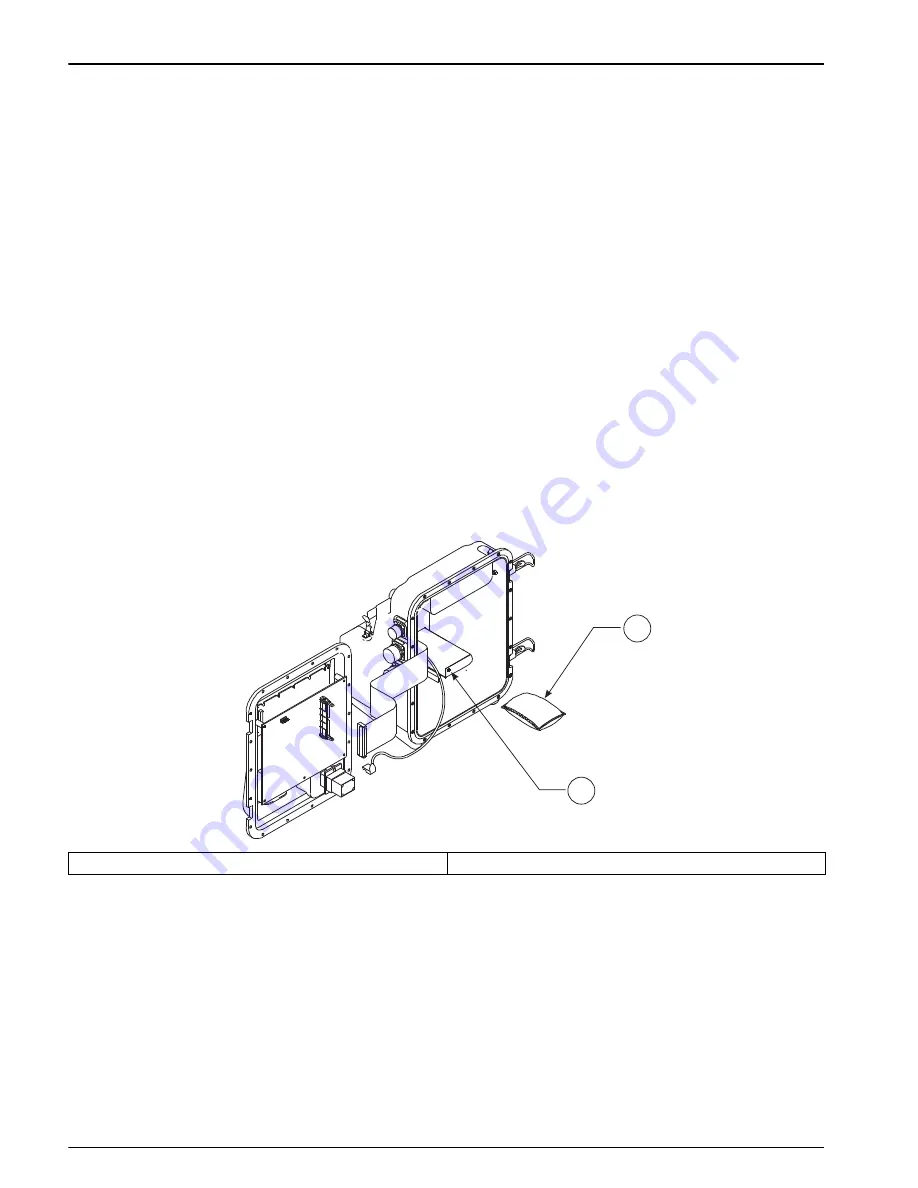

9.5 Replacing the Internal Desiccant Module

The Internal Desiccant Module (P/N 787) consists of a moisture absorbing material inside

a poly bag. The module should be replaced if the Internal Case Humidity Indicator on the

front panel turns pink.

To replace the desiccant module, proceed as follows:

1.

Remove the screw holding the desiccant door in place and remove the door

(

2.

Slide out the old desiccant module and slide in a fresh one

3.

Reattach the desiccant door.

The desiccant module cannot be recharged by heating. Do not attempt to bake the

desiccant module in an oven to remove the moisture because this could be a fire hazard.

Figure 21 Replacing Internal Desiccant Module

9.6 Replacing the Internal Case-Humidity Indicator Disc

After replacing the desiccant module and re-sealing the case, the Internal Case Humidity

Indicator Disc (P/N 2660) will return to its original blue color within 24 hours.

If the indicator disc fails to return to blue after replacing the desiccant module, replace the

disc. The indicator disc is held in place by a small clip and screw. To gain access to the

indicator disc you must first remove the CPU board. Be sure to observe proper handling

for static sensitive CMOS devices.

1

Internal Module (P/N 787)

2

Remove desiccant access screw and door.

2

1

Summary of Contents for Sigma 950

Page 2: ......

Page 6: ...4...

Page 20: ...18 Introduction...

Page 34: ...32 Basic Programming Setup...

Page 50: ...48 Sensor Installation...

Page 82: ...80 Maintenance...

Page 83: ...81 Appendix A Program Flow Charts Figure 22 Overview of Basic Program Menus...

Page 84: ...82 Program Flow Charts Figure 23 Setup Flow Chart...

Page 85: ...83 Program Flow Charts Figure 24 Options Flow Chart...

Page 86: ...84 Program Flow Charts Figure 25 Alarms Menus Flow Chart...

Page 87: ...85 Program Flow Charts Figure 26 Calibration Menus Flow Chart Page 1...

Page 88: ...86 Program Flow Charts...

Page 102: ...100 Programming Features...

Page 106: ...104 Primary Devices Head Measurement Locations...

Page 126: ...124 SCADA Modbus System Guidelines...