ES0755 rev A 1/11

21

range of 700 to 750 psi. This is the “blocked system” pressure.

If necessary this pressure can be adjusted by turning the pressure adjusting screw (the vertically oriented

screw with locknut), on the pump in a clockwise direction to increase pressure and counterclockwise to

decrease pressure.

The tool changer is now fully connected and ready for alignment.

NOTE

: Final alignment of the toolchanger to the machine spindle must be

performed before the toolchanger can be used to change tools.

Tool Changer Installation

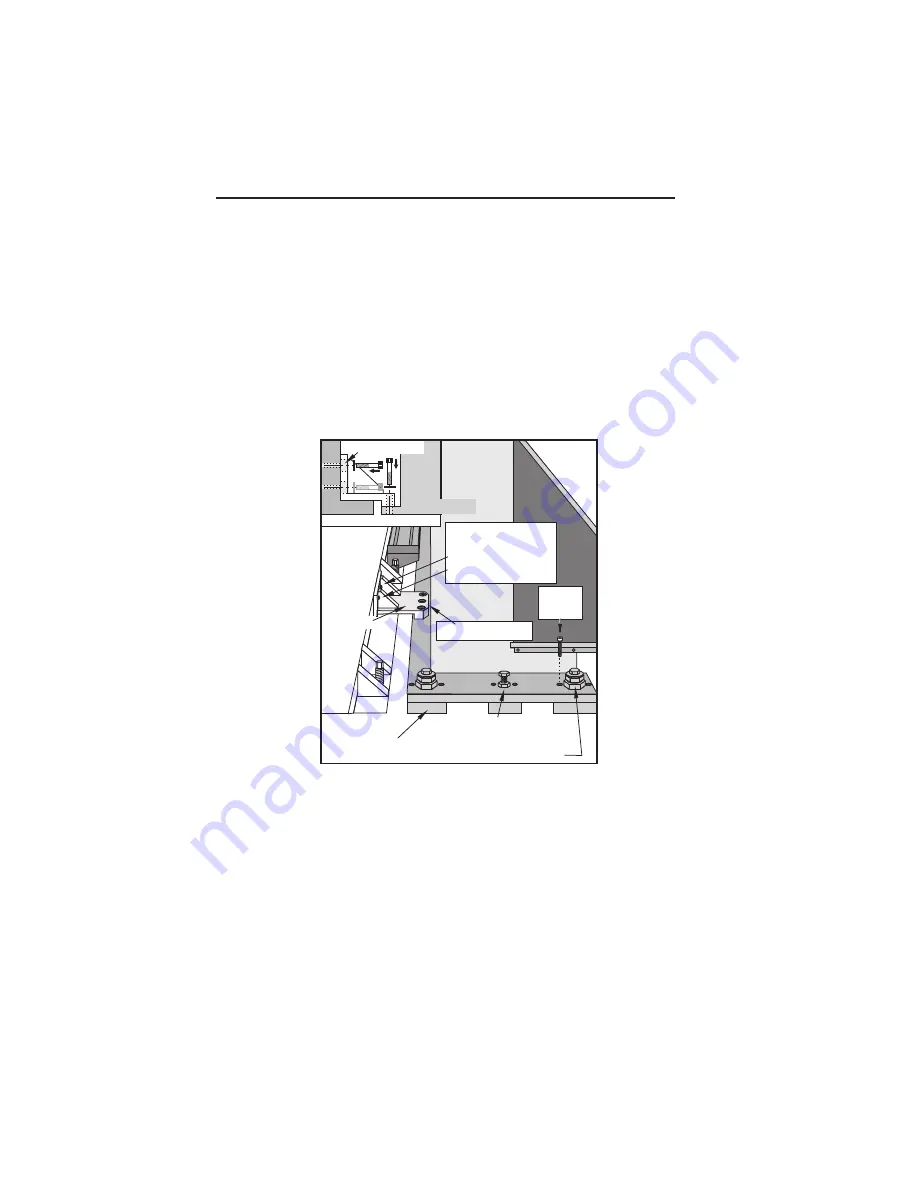

1. Before installing the eight leveling blocks on the bottom of the toolchanger base plate, thread in the metric

SHCS into the holes located on each side of the leveling screws.

2. Temporarily block tool changer up on its base plate and install the eight levelling blocks on the bottom of

the base plate. Secure them with metric SHCS installed above. The leveling blocks with center holes are for

the Main Leveling Screws in each corner; the solid leveling blocks are for the Intermediate Leveling Screws.

3. Verify that the four main leveling screws (the large hollow screws located at all four corners) and the four

intermediate leveling screws (the hex head bolts located on each of the four sides of the base plate) are ad-

justed so that they are flush with the bottom of the tool changer’s base plate.

Center Holes In

HS3 Base With

Vertical Slots Of

Bracket

(3) M16x60mm

HS3

Toolchanger

HS3

Intermediate

Leveling Screws

Main Leveling Screws

Leveling Blocks

Metric

SHCS

Bracket Slots

Toolchanger

Bracket

Tool Changer and Base Plate

4. Lift tool changer with arm mechanism facing toward front of machine. Move the tool changer over the top of

the pre-installed anchor bolts and lower it such that the hollow leveling screws slide over the anchor bolts.

5. An alignment bracket is used to provide initial “rough” alignment of the tool changer to the horizontal mill.

Attach the alignment bracket to the base of the tool changer using three M16 X 60mm metric socket head cap

screws (Haas P/N 40-0039).

Install, but do not tighten screws at this time.

In addition, it may be necessary

to move the tool changer’s base plate a small amount to bring the alignment bracket into its proper position.

6. Place a bubble level on the tool changer’s base and using the four main leveling screws (the large 60mm

hex screws located in the corners of the base plate) bring the tool changer base plate into level. During

this leveling procedure, verify that the height of the slots on the vertical face of the alignment bracket are

at the same elevation as the threaded holes in the pad located on the side of the milling machine’s base. If

necessary, readjust the leveling screws to bring the alignment bracket to the proper elevation.

7. When the tool changer is level and the four slotted holes in the alignment bracket are lined up with the

threaded holes in the pad, attach the alignment bracket to the base of the mill using four 3/8-16 x 1¼ socket

head cap screws. Finish attaching the bracket by tightening the three M16 cap screws.