2-11

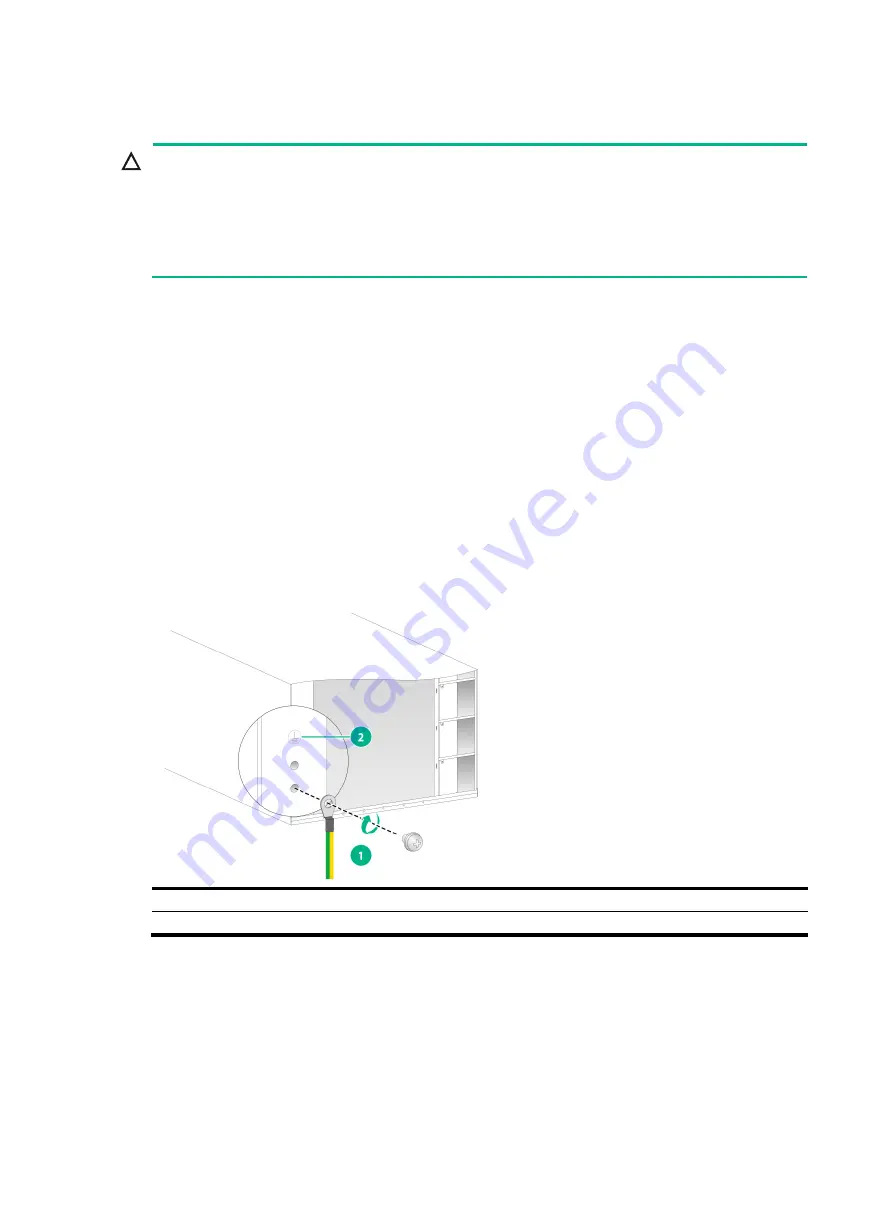

Grounding the device

CAUTION:

•

Reliably grounding the device is crucial to lightning protection and EMI protection. Ground the

device reliably before you use it.

•

Use the grounding cable (yellow-green grounding cable) provided with the device.

•

Connect the grounding cable to the earthing system in the equipment room. Do not connect it to

a fire main or lightning rod.

You can ground the device by connecting the grounding cable to a grounding strip in the equipment

room or the grounding strip on the rack.

To connect the grounding cable to a grounding strip:

1.

Unpack the grounding cable.

The single-hole or two-hole grounding lug of the grounding cable is used for connecting the

chassis. The ring terminal of the grounding cable is used for connecting the grounding strip.

2.

Remove the M6 grounding screw from the grounding holes at the rear of the chassis.

A grounding sign is provided with the grounding holes, as shown by callout 2 in

3.

Use an M6 grounding screw to attach the grounding lug of the grounding cable to the chassis,

as shown by callout 1 in

As a best practice, use a torque of 50 kgf-cm (43.40 lbf-in).

4.

Connect the ring terminal of the grounding cable to a grounding strip in the equipment room or

the grounding strip on the rack.

Figure 2-12 Connecting the grounding cable (for the S12516G-EF)

(1) Use the grounding screw to attach the single-hole grounding lug to the grounding point

(2) Grounding sign