123456789012345

123456789012345

123456789012345

123456789012345

123456789012345

123456789012345

123456789012345

123456789012345

123456789012345

123456789012345

123456789012345

123456789012345

123456789012345

123456789012345

123456789012345

123456789012345

123456789012345

123456789012345

123456789012345

123456789012345

123456789012345

123456789012345

123456789012345

123456789012345

123456789012345

123456789012345

123456789012345

123456789012345

123456789012345

123456789012345

123456789012345

123456789012345

123456789012345

123456789012345

123456789012345

123456789012345

123456789012345

123456789012345

123456789012345

123456789012345

123456789012345

123456789012345

123456789012345

123456789012345

123456789012345

123456789012345

123456789012345

123456789012345

123456789012345

123456789012345

123456789012345

123456789012345

123456789012345

123456789012345

123456789012345

123456789012345

123456789012345

123456789012345

123456789012345

123456789012345

123456789012345

123456789012345

123456789012345

123456789012345

123456789012345

123456789012345

123456789012345

123456789012345

123456789012345

123456789012345

123456789012345

123456789012345

123456789012345

123456789012345

123456789012345

123456789012345

123456789012345

123456789012345

123456789012345

123456789012345

123456789012345

123456789012345

123456789012345

123456789012345

123456789012345

123456789012345

123456789012345

123456789012345

123456789012345

123456789012345

123456789012345

123456789012345

123456789012345

123456789012345

123456789012345

123456789012345

123456789012345

123456789012345

123456789012345

123456789012345

123456789012345

123456789012345

123456789012345

123456789012345

123456789012345

123456789012345

123456789012345

123456789012345

123456789012345

123456789012345

123456789012345

123456789012345

123456789012345

123456789012345

123456789012345

123456789012345

123456789012345

123456789012345

123456789012345

123456789012345

123456789012345

123456789012345

123456789012345

123456789012345

123456789012345

123456789012345

123456789012345

123456789012345

123456789012345

123456789012345

123456789012345

123456789012345

123456789012345

123456789012345

123456789012345

123456789012345

123456789012345

123456789012345

123456789012345

123456789012345

123456789012345

123456789012345

123456789012345

123456789012345

123456789012345

123456789012345

123456789012345

123456789012345

123456789012345

123456789012345

123456789012345

123456789012345

123456789012345

123456789012345

123456789012345

123456789012345

123456789012345

123456789012345

123456789012345

123456789012345

123456789012345

123456789012345

123456789012345

123456789012345

123456789012345

123456789012345

123456789012345

123456789012345

123456789012345

123456789012345

123456789012345

123456789012345

123456789012345

123456789012345

123456789012345

123456789012345

123456789012345

123456789012345

INSTALLATION AND SERVICE MANUAL 959R

184981-02

29

CAUTION

All maintenance and

adjustments must be done

by an authorized service

technician.

CAUTION

To avoid electrical shock

and contact with moving

parts, make sure all

switches are in the "OFF"

position and that the

main power supply is

disconnected. Some

freezers have more than

one disconnect switch.

operation, or every six months,

whichever occurs first.

3. OVERFILLING OR UNDERFILLING

– If a gear reducer is overfilled with

oil, the energy used in churning the

excessive oil can result in overheat-

ing. If the gear reducer is underfilled,

the resultant friction can cause

overheating. If underfilling occurs, fill

the gear reducer to the oil level plug

hole.

NOTE

: Normal operation can generate

temperatures up to 200°F (93°C). If

overheating occurs due to overfilling, shut

down the drive, remove the oil level plug

and allow excess oil to drain. Reinst all the

oil level plug, and restart the drive.

4.

DRAINING OIL – Open oil drain

plugs. Drain oil with speed reducer

at normal operating temperature.

5.

PROPER OIL LEVEL – Fill until oil

is at the bottom of the threads in the

oil level plug hole.

6.

INSPECTION – When changing oil,

always inspect all areas around the

reducer for traces of oil. If oil is

found in the immediate area, rep air

the leak (usually an oil seal) and

check for proper oil level.

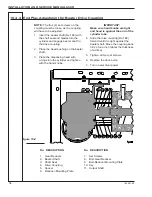

The gear reducers are heavy duty,

worm-geared units manufactured to H.

C. Duke & Son, Inc. specifications. The

following lubrication procedures should

be followed.

CAUTION

To avoid electrical shock

and contact with moving

parts, make sure all

switches are in the "OFF"

position and that the main

power supply is

disconnected. Some

freezers have more than

one disconnect switch.

IMPORTANT:

DO NOT overfill. Overfilling can

damage the gear reducer.

1. OIL – Each gear reducer is charged

with a special oil and will not mix

with other types of oil. When adding

or changing oil always verify the

specific oil used by referring to the

nameplate located on the gear

reducer.

2. OIL CHANGING – Under normal

conditions, the oil should be

changed after every 2500 hours of

10.1 Gear Reducer Lubrication Instructions

10 Maintenance and Adjustments