Appendix A:

Fist Grip: compatible with cable diameters from 3/16” - 5/8”.

Efficiency ratings for wire rope end terminations are based upon the catalog breaking

strength of wire rope. The efficiency rating of a properly prepared loop or thimble-eye

termination for clip sizes 1/8” through 7/8” is 80%, and for 1” through 3½” is 90%.

!

WARNING

Prepare wire rope end termination only as instructed.

DO NOT use vinyl/plastic coated wire rope.

Apply first load to test the assembly. This load should be of

equal or greater weight than loads expected in use.

The number of clips shown (see Table 1) is based upon using RRL or RLL wire rope, 6 x 19 or 6 x 37 Class FC or

IWRC, IPS or XIP, or XXIP. If Sealed construction or similar large outer wire type construction in the 6 x 19 Class is

to be used for sizes 1” or larger, add one additional clip. If a pulley (sheave) is used for turning back the wire

rope, add one additional clip.

The number of clips shown also applies to rotation-resistant RRL wire rope, 8 x 19 Class IPS, XIP, or XXIP sizes

1½” and smaller; and to rotation-resistant RRL wire rope, 19 x 7 Class IPS, XIP, or XXIP sizes 1½” and

smaller. For other classes of wire rope not mentioned above, we recommend contacting Crosby Engineering to

ensure the desired efficiency rating. The style of wire rope termination used for any application is the

obligation of the user.

1. Refer to Table 1 in following these instructions. Turn back specified amount of rope from thimble or loop.

Apply first clip one base width from dead end of rope. Use torque wrench to evenly tighten clip, alternating

from one nut to the other until reaching the recommended torque.

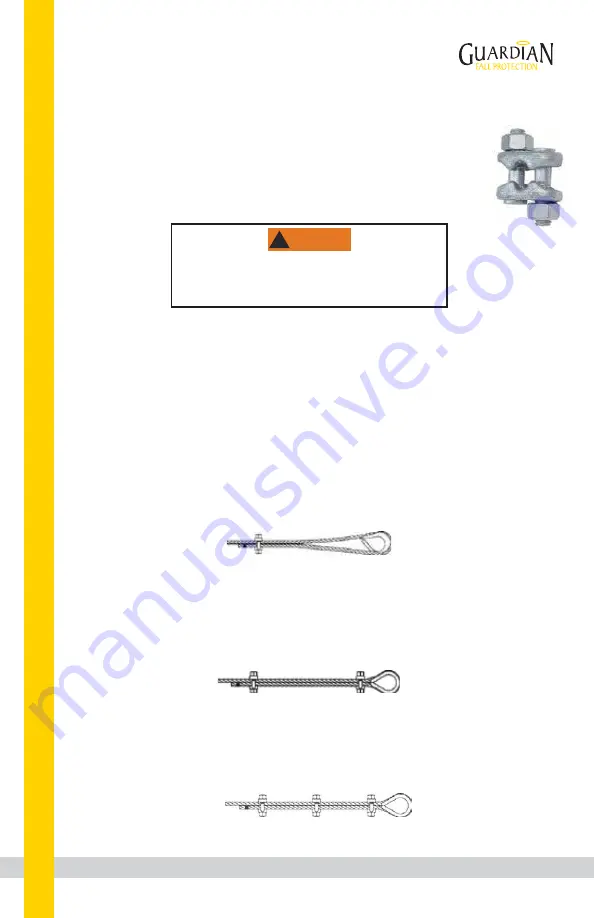

FIGURE 1

FIGURE 2

3. When three or more clips are used, space additional clips equally between first two. Take up rope slack,

use torque wrench to tighten on each clip evenly, alternating from one nut to the other until reaching

recommended torque.

FIGURE 3

Live End

Dead End

G

ua

rd

ia

n

Fa

ll

Pr

ot

ec

tio

n

6

30

5

S.

2

31

st

S

t.

, K

en

t,

W

A

9

80

32

p

ho

ne

: (

80

0)

4

66

-6

38

5

f

ax

: (

80

0)

6

70

-7

89

2

w

w

w

.g

ua

rd

ia

nf

al

l.c

om

8

2. When two clips are required, apply the second clip as near the loop or thimble as possible. Use torque

wrench to evenly tighten clip, alternating until reaching the recommended torque. When more than two clips

are required, apply the second clip as near the loop or thimble as possible, turn nuts on second clip firmly, but

do not tighten.