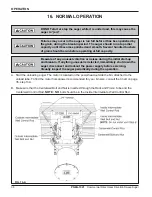

OPERATION

35

PNEG-1521

Commercial Direct Gear Drive Bin Sweep Auger

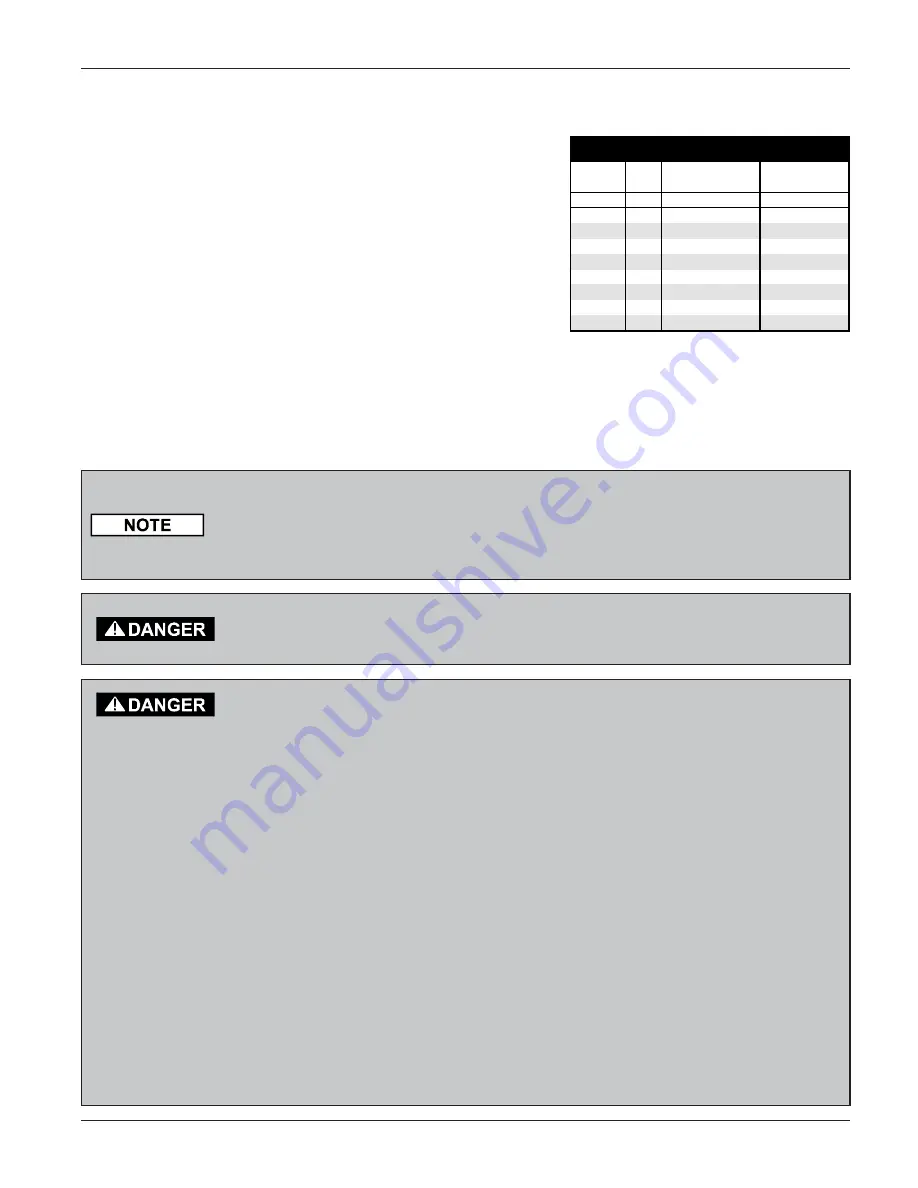

13. MOTOR SELECTION

A. The following horsepower recommendations are for

conveyance of reasonably dry grain. Grain with moisture

content above 15% will require a greater horsepower to obtain

the designed capacity. The maximum possible capacity will be

less with high moisture grain than it will be with dry grain. Use

an electric motor of the correct size that operates at 1750

RPM. DO NOT use a motor size that is greater than what is

shown for the largest bin size in your column.

B. Consideration should be given to the proper size auger for a

batch drying or any intermittent type of operation. When augers

are stopped and restarted under full load, damage to the auger

may result. Starting the auger at a reduced grain load will be

better than starting it at full load. Startup will be easier and

convey more efficiently if the auger is kept from absolute filling.

The auger capacity can fluctuate greatly under a variety of different

conditions. Moisture content, different commodities, the amount of foreign

matter, and auger speeds affect the performance of the auger and it s

efficiency. Moisture content of 25% can reduce auger capacity by as much as

40% under some conditions.

A main power disconnect switch capable of being locked only in the off

position should be used. The Switch should be locked out whenever work is

being done on the Direct Gear Drive Bin Sweep.

1. Electric motors and the controls should be installed by a qualified

electrician and must meet the standards set by the National Electric Code

and all state and local codes.

2. A main power disconnect switch capable of being locked only in the OFF

position shall be provided. This disconnect shall be locked whenever

work is being done on the auger .

3. A magnetic starter should be used to protect your motor when starting and

stopping the Unload system. The magnetic starter should stop the motor

in case of a power interruption, conductor fault, low voltage, circuit

interruption, or a motor overload. The motor must then be restarted

manually. Some motors have built-in thermal overload protection. If this

type of a motor is being used, use only those motors with a manual reset.

4. The motor starting controls must be located outside of the bin. Locate the

motor starting controls outside of the bin, but near the bin door so the

operator has full view of the operation inside the bin.

5. Disconnect the power before resetting the motor overloads.

6. Reset controls and the motor staring controls must be located so that the

operator has full view of the entire operation.

7. Make certain that all electric motors are grounded.

8. Shut off and lockout the power to adjust, service, or clean the Unload

system.

Horizontal and

25° Powerheads

12" Comm.

Vertical

Bin Dia.

HP

Belt Quantity

Belt Quantity

36'

15

3

3

42'

15

3

3

48'

15

3

3

54'

15

3

3

60'

15

3

3

72'

20

4

3

75'

20

4

3

78'

20

4

3

Motor Selection