10

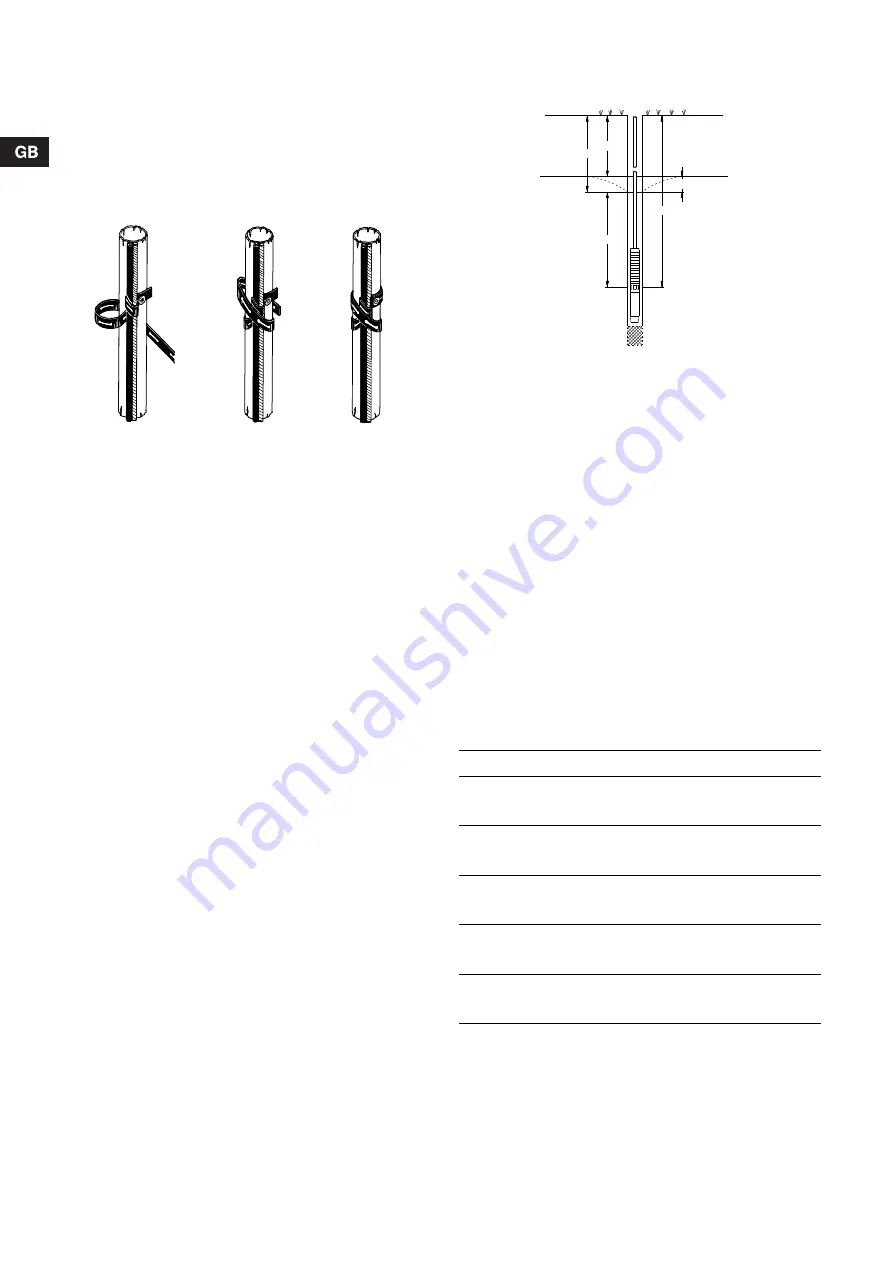

5.5 Cable fitting

Cable clips must be fitted every 3 metres to fix the submersible

drop cable and the straining wire, if fitted, to the riser pipe of the

pump.

GRUNDFOS supplies cable clip sets on request. The set consists

of a 1.5 mm thick rubber band and 16 buttons.

Cable fitting: Cut off the rubber band so that the piece with no

slit becomes as long as possible.

Insert a button in the first slit.

Position the wire alongside the submersible drop cable, fig. 12.

Fig. 12

Wind the band once around the wire and the cable.

Then wind it tightly at least twice around the pipe, wire and the

cable.

Push the slit over the button and then cut off the band.

Where large cable cross-sections are used, it will be necessary to

wind the band several times.

When flanged pipes are used, the cable clips should be fitted

above and below each joint.

5.6 Lowering the pump

It is recommended to check the borehole by means of an inside

calliper before lowering the pump to ensure unobstructed pas-

sage.

Lower the pump carefully into the borehole, taking care not to

damage the motor cable and the submersible drop cable.

Note: Do not lower or lift the pump by means of the motor cable.

5.7 Installation depth

The dynamic water level should always be above the suction

interconnector of the pump, see section 3.2 Positional require-

ments and fig. 13.

Minimum inlet pressure is indicated in the NPSH curve for the

pump.

The minimum safety margin should be 1 metre head.

It is recommended to install the pump so that the motor part is

above the well screen in order to ensure optimum cooling, see

section 3.4 Liquid temperatures/cooling.

When the pump has been installed to the required depth, the

installation should be finished by means of a borehole seal.

6. Start-up and operation

6.1 Start-up

When the pump has been connected correctly and it is sub-

merged in the liquid to be pumped, it should be started with the

discharge valve closed off to approx. 1/3 of its maximum volume

of water.

Check the direction of rotation as described in section

4.5.1 Checking of direction of rotation.

If there are impurities in the water, the valve should be opened

gradually as the water becomes clearer. The pump should not be

stopped until the water is completely clean, as otherwise the

pump parts and the non-return valve may choke up.

As the valve is being opened, the drawdown of the water level

should be checked to ensure that the pump always remains sub-

merged.

The dynamic water level should always be above the suction

interconnector of the pump, see section 3.2 Positional require-

ments and fig. 13.

Fig. 13

L1:

Minimum installation depth below dynamic water level.

Minimum 1 metre is recommended.

L2:

Depth to dynamic water level.

L3:

Depth to static water level.

L4:

Drawdown. This is the difference between the dynamic

and the static water levels.

L5:

Installation depth.

If the pump can pump more than yielded by the well, it is recom-

mended to fit the GRUNDFOS control unit, type CU 3, or some

other type of dry-running protection.

If no water level electrodes or level switches are installed, the

water level may be drawn down to the suction interconnector of

the pump and the pump will then draw in air.

Long time operation with water containing air may damage the

pump and cause insufficient cooling of the motor.

6.2 Operation

6.2.1 Minimum flow rate

To ensure the necessary cooling of the motor, the pump should

never be set so low that the cooling requirements specified in

section 3.4 Liquid temperatures/cooling cannot be met.

6.2.2 Frequency of starts and stops

TM

00 13

69 50

92

T

M

00

10

41

36

9

5

Motor type

Number of starts

MS 6000

Minimum 1 per year is recommended.

Maximum 30 per hour.

Maximum 300 per day.

MMS 6000

Minimum 1 per year is recommended.

Maximum 15 per hour.

Maximum 360 per day.

MMS 8000

Minimum 1 per year is recommended.

Maximum 10 per hour.

Maximum 240 per day.

MMS 10000

Minimum 1 per year is recommended.

Maximum 8 per hour.

Maximum 190 per day.

MMS 12000

Minimum 1 per year is recommended.

Maximum 5 per hour.

Maximum 120 per day.

L2

L3

L1

L5

L4

Summary of Contents for SP-G

Page 1: ...SP G GRUNDFOS INSTRUCTIONS Installation and operating instructions ...

Page 17: ...112 ...

Page 18: ...113 ...

Page 19: ...114 ...