English (GB)

11

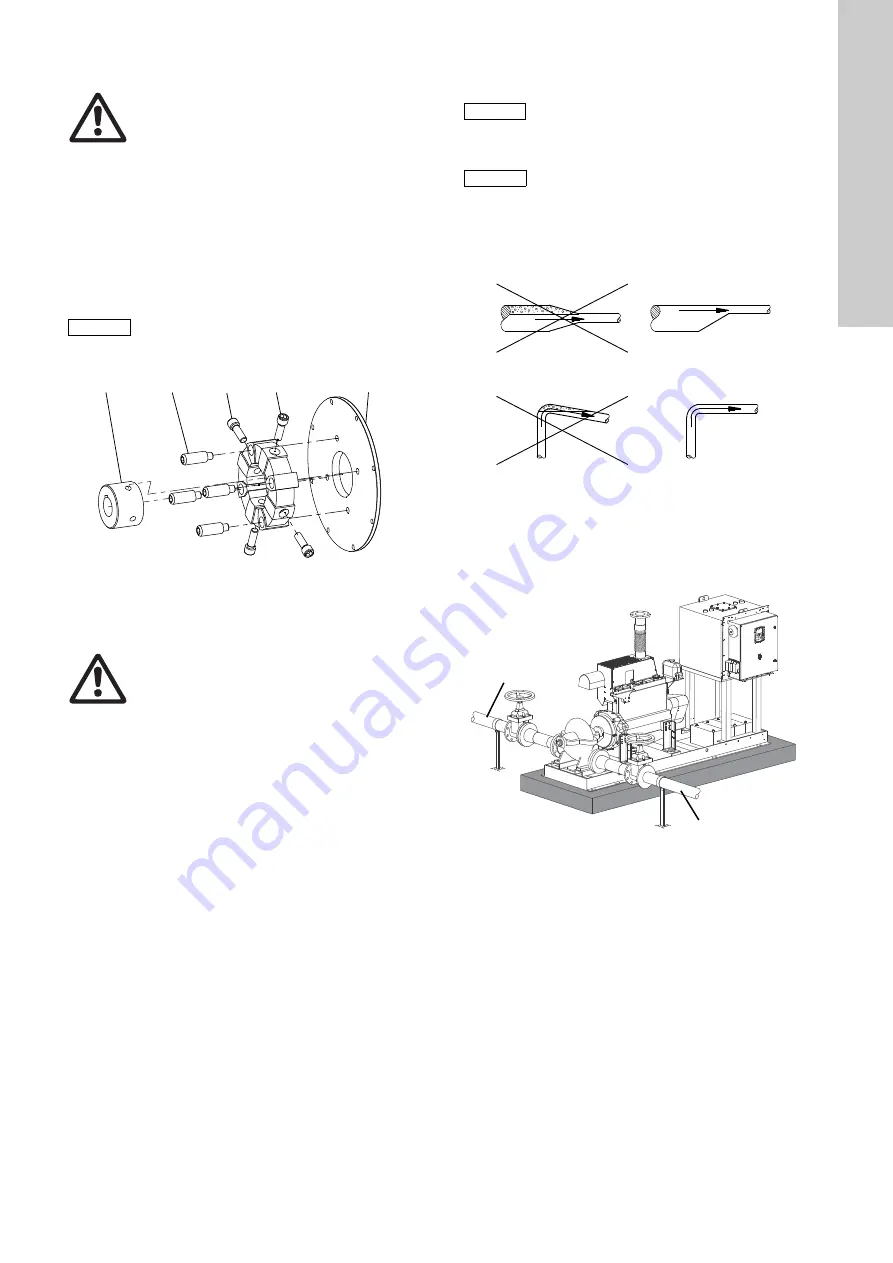

Checking the alignment

1. Disconnect the negative pole of the starter battery.

2. Remove the coupling guard.

3. Check the alignment according to

the installation and

operating instructions for the coupling.

4. Refit the coupling guard.

5. Reconnect the negative pole of the starter battery.

Aligning pump and engine

Fig. 14

Axial and radial fixation of the clamping hub of the

coupling

6. Align the coupling according to the installation and operating

instructions for the coupling.

6.5 Pipe connection

The pipes must be installed as straight as possible and be of an

adequate size. Take the pump inlet pressure into consideration.

Install the pipes so that air locks are avoided. This applies

especially to the suction side of the pump. See fig. 15.

Fig. 15

Installation of pipes

Secure the pipes close to the pump on the suction and discharge

side with pipe brackets attached to the building (wall, ceiling,

floor). See fig. 16.

The pipes should lie true against the pump flanges without being

stressed. Otherwise, the pump may be damaged.

Fig. 16

Fixing points of the pipes

Install isolating valves on both sides of the pump.

Connect the suction pipe to suction pump port and the discharge

pipe to the discharge pump port.

6.6 Priming tank and test pipe

If the pump set is supplied from a storage tank and the suction

height is negative, install a pump priming tank on the suction side

in accordance with local regulations. See also the standard

applying to the pump set.

Install a test pipe running from the discharge pipe to the storage

tank. The discharge pipe and the test pipe must be fitted with

isolating valves.

If the pump set is fed directly from the public water supply, the

test pipe must have a free outlet according to the standard

applying to the pump set.

Warning

Disconnect the battery cable before you remove the

coupling guard.

Beware of the sharp edges of the coupling guard.

Wear protective gloves.

Caution

Axial and radial screws can be reused maximum

three times.

Do not use threadlocker as it may damage the rubber

material.

T

M

04

00

58

49

07

Warning

After checking or adjusting the alignment, fit the

coupling guard.

1

4

2

5

3

Caution

The pipework must not stress the pump housing or

transfer any forces to the pump housing.

See permissible flange forces and torques in section

Note

The discharge pipe must have a port for venting and

priming the pump. See section

.

TM

00

22

63

33

93

TM

06

18

64

33

14

Discharge pipe

Suction pipe