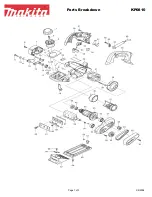

Figure 22. Gearbox area components.

Figure 23. Pulley area components.

Figure 24. Cutterhead installed in planer.

Model T32591 (Mfd. 05/21)

-7-

22. Turn speed selector switch counterclockwise

to speed "1" to grasp positioning pin with "U"

bracket.

23. Re-install screws removed from gearbox in

Step 24 on Page 3 of Removing Existing

Cutterhead instructions.

24. Test for smooth operation of speed selection

assembly by cycling speed selector switch

from "1" to "2" and then back to "1".

25. Re-install spacer on front roller.

26. Re-install sprockets and chain on front and

rear rollers (see

Figure 22).

27. Re-attach spring to chain tensioner. Verify

tensioner is engaged with chain, as shown in

Figure 22.

28. Re-install retaining rings on front and rear

rollers (see

Figure 22).

29. Re-install gearbox cover.

30. Re-install sprockets and chain on front and

rear rollers in pulley area (see

Figure 23).

31. Re-install chain tensioner and re-attach

spring. Verify tensioner is engaged with chain

(see

Figure 23).

32. Re-install pulley cover.

33. Re-install dust shroud into fan housing.

Note: DO NOT re-install cutterhead lock

lever! Cutterhead lock lever is not compatible

with the Model T32591.

34. Rotate dust shroud towards cutterhead.

Verify alignment arrow on fan housing aligns

with

CLOSED line on dust shroud.

35. Re-install red wing nuts on dust shroud.

36. Re-install top cover.

37. Remove any cardboard used to protect plan-

er table.

38. Connect machine to power and follow all

procedures outlined in your planer manual for

adjustment and calibration.

Chain Tensioner

Front Roller

Rear Roller

Spring

Chain

Chain Tensioner Assembly

Sprocket

Chain

Cutterhead Pulley

Sprockets

Retaining Rings