-52-

Model G4000 (Mfg. Since 8/09)

Adjusting Gibs

the gibs that affect the accuracy of the carriage,

cross slide, and compound slide movements along

their ways can be adjusted. the carriage uses a

gib clamp located on the rear of the carriage

saddle, and the cross slide and compound slide

use a wedge-shaped gib sandwiched between

the component base and the way.

the goal of gib adjustment is to remove unneces-

sary sloppiness without causing the ways to bind.

tight gibs make the movements more accurate,

but harder to perform. Loose gibs make the move-

ments sloppy, but easier to perform.

Tools Needed

Qty

hex Wrench 5mm .............................................. 1

Carriage Gib Clamp

1. disConnECt LAthE FroM poWEr!

2. Loosen the three cap screws that secure the

gib clamp underneath the rear of the carriage

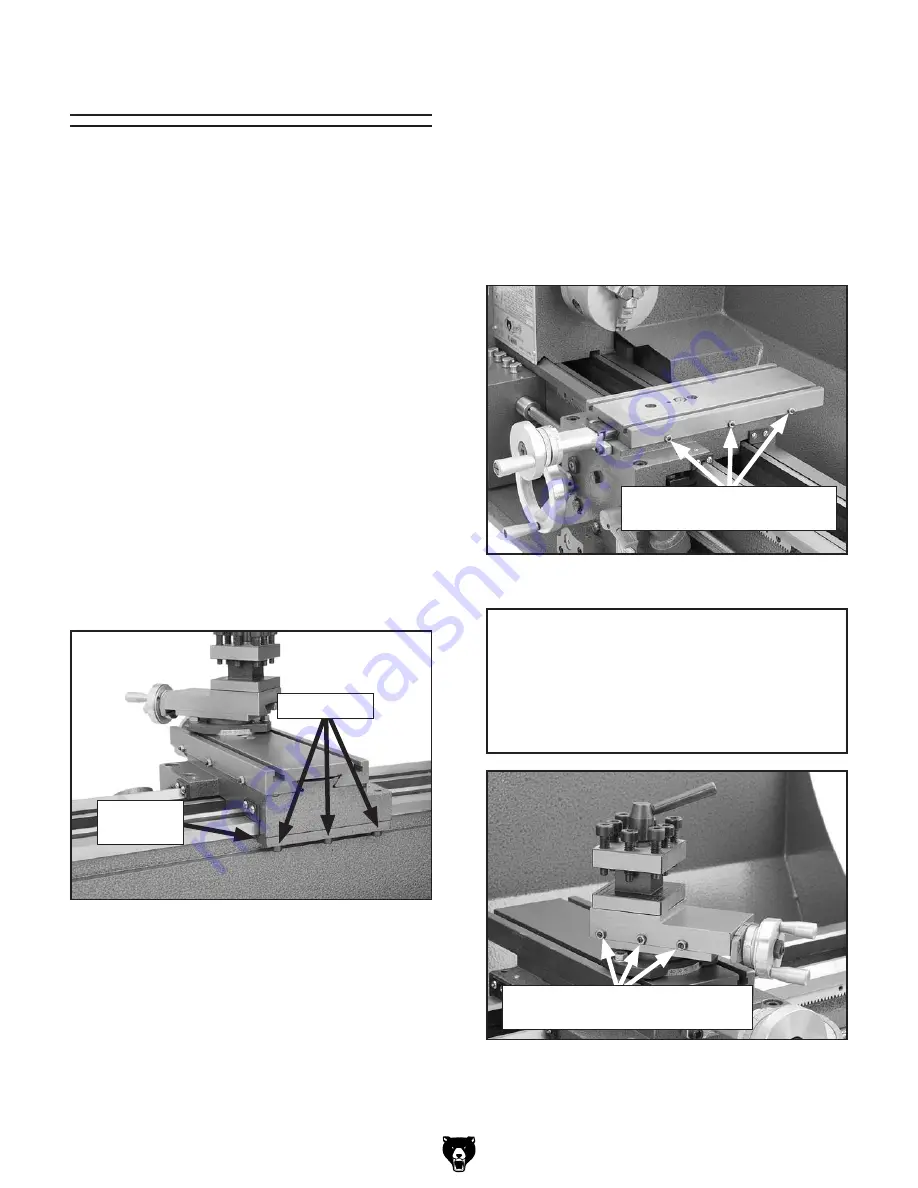

saddle, as shown in

figure 82.

NOTICE

Excessively loose gibs may cause poor

workpiece finishes, and may cause

undue wear of sliding surfaces and ways.

Excessively tight gibs may cause prema-

ture wear of the sliding devices.

Tools Needed

Qty

Wrench 7mm ..................................................... 1

standard screwdriver #1 ................................... 1

Cross Slide & Compound Slide Gibs

1. disConnECt LAthE FroM poWEr!

2. Loosen the three hex nuts on the side of the

device (see

figures 83–84).

figure 83. Cross slide gib adjustment hex nuts

and set screws.

Cross slide gib Adjustment

hex nuts & set screws

figure 82. Carriage gib clamp cap screws (as

viewed from the rear of the carriage).

Cap screws

Carriage

gib Clamp

figure 84. Compound slide gib adjustment hex

nuts and set screws.

Compound slide gib Adjustment

hex nuts & set screws

3. Manually move the carriage back-and-forth

to make sure the gib clamp is loose, then

tighten each of the cap screws just until you

feel resistance.

4. re-check the carriage movement and loosen

or tighten the cap screws equally until you are

satisfied with the gib clamp adjustment.