Model G1033/X/Z (Mfd. Since 02/19)

-39-

Setting Feed Roller,

Chip Breaker &

Pressure Bar

Heights

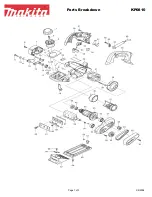

A & B

Infeed

Roller

Outfeed

Roller

Pressure

Bar

Chip

Breaker

C

D

BDC

(Bottom Dead Center)

Figure 50. Planer component recommended

clearances (illustration is not to scale).

Dist. Below Knife/Insert at BDC (Figure 50)

A. Infeed Roller ....................................... 0.040"

B. Chip Breaker....................................... 0.040"

C. Pressure Bar.......................................0.008"

D. Outfeed Roller .................................... 0.020"

It is essential that the feed rollers, chip breaker,

and pressure bar are set at the correct distance

below the cutterhead knives/inserts at BDC (bot-

tom dead center) to ensure that the workpiece

moves through the planer evenly and the correct

distance from the cutterhead knives/inserts.

To ensure accurate results and make the adjust-

ment process quicker and easier, we recommend

using a Rotacator for these adjustments (refer to

Page 30).

If a Rotacator is not available, a 6' 2x4 cut into two

even-sized pieces and a feeler gauge set can be

used, but care must be taken when jointing the

wood to achieve accurate results.

4. If V-belts need to be replaced, raise motor to

release belt tension (see next step for instruc-

tions), roll them off pulleys, then replace with

a matched set of three.

5. To adjust V-belt tension, loosen both top

motor mount hex nuts (see

Figure 48 on

Page 38), then adjust bottom hex nuts to

raise or lower motor.

Note: V-belts are correctly tensioned when

there is approximately

3

⁄

4

" deflection when

moderate pressure is applied to them midway

between pulleys, as illustrated in

Figure 49.

Cutterhead

Pulley

Approximately

3

⁄

4

" Deflection

Motor

Pulley

Figure 49. Belt deflection when V-belts are

correctly tensioned.

6. After V-belts are correctly tensioned, tighten

top motor mount hex nuts, then re-install

cabinet cover and belt cover.

Summary of Contents for G1033X

Page 76: ......