-44-

Model G0926 (Mfd. Since 11/20)

5. Adjust bearings as necessary to force blade

to be 90° to vise, then tighten hex nuts to

secure.

Note: Since bearings twist blade into posi-

tion, it is acceptable if there is 0.001"–0.002"

gap between blade and front or back of bear-

ing. Just make sure not to squeeze blade too

tightly with bearings. After guide bearings

are set, you should be able to rotate guide

bearings (although they will be stiff) with your

fingers.

6. Install front blade guide guard before resum-

ing operation.

— If square evenly touches both face of vise

and blade, no adjustment is necessary.

— If square does not evenly touch blade

when evenly touching vise, proceed to

Step 4.

4. Loosen hex nuts securing eccentric bushings

attached to guide bearings (see

Figure 58).

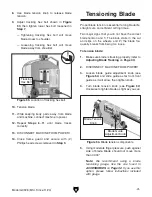

Note: There is a guard on front blade guide

assembly. Remove flat head screws shown

in

Figure 60 to remove guard and access

bushing.

Figure 60. Front blade guide guard.

Guard

Figure 59. Square positioned against vise and

blade to check blade squareness.

3. Put square against face of vise and move it

over to blade (see

Figure 59).

Square

Summary of Contents for G0926

Page 56: ......