Model G0920 (Mfd. Since 10/20)

-35-

Review the troubleshooting procedures in this section if a problem develops with your machine. If you need

replacement parts or additional help with a procedure, call our Technical Support.

Note: Please gather the

serial number and manufacture date of your machine before calling.

SECTION 7: SERVICE

Troubleshooting

Motor & Electrical

Symptom

Possible Cause

Possible Solution

Machine does

not start, or

power supply

breaker

immediately

trips after

startup.

1. Machine circuit breaker tripped.

2. Incorrect power supply voltage or circuit size.

3. Power supply circuit breaker tripped or fuse

blown.

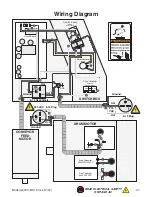

4. Motor wires connected incorrectly.

5. Start capacitor at fault.

6. Extension cord too long.

7. Wiring broken, disconnected, or corroded.

8. ON/OFF or machine circuit breaker switch at

fault.

9. Centrifugal switch adjustment/contact points

at fault.

10. Circuit board at fault.

11. Drum motor or drum motor bearings at fault.

1. Reset circuit breaker.

2. Ensure correct power supply voltage and circuit size.

3. Ensure circuit is free of shorts. Reset circuit breaker or

replace fuse.

4. Correct motor wiring connections.

5. Test/replace if at fault.

6. Move machine closer to power supply; use shorter

extension cord.

7. Fix broken wires or disconnected/corroded

connections.

8. Replace switch/circuit breaker.

9. Adjust centrifugal switch/clean contact points. Replace

either if at fault.

10. Inspect/replace if at fault.

11. Replace drum motor.

Machine

turns

ON but

conveyor belt

does not start/

stalls.

1. Motor brushes worn out.

2. Variable-speed dial/potentiometer at fault.

3. Circuit board at fault.

4. Conveyor feed motor or bearings at fault.

1. Remove/replace both brushes as a set (

Page 45).

2. Inspect/replace if at fault.

3. Inspect/replace if at fault.

4. Replace conveyor feed motor.

Machine

stalls or is

underpowered.

1. Workpiece material not suitable for machine.

2. Feed rate/sanding depth too great.

3. Machine undersized for task.

4. Too much pressure on pressure rollers.

5. Motor overheated, tripping machine circuit

breaker.

6. Run capacitor at fault.

7. Extension cord too long.

8. Centrifugal switch/contact points at fault.

9. Motor or motor bearings at fault.

1. Only sand wood/ensure moisture is below 20%.

2. Reduce feed rate (

Page 27)/sanding depth (Page 25).

3. Clean (

Page 33)/replace (Page 29) sandpaper.

4. Reduce pressure roller pressure.

5. Clean motor/let cool, and reduce workload. Reset

breaker.

6. Test/repair/replace.

7. Move machine closer to power supply; use shorter

extension cord.

8. Adjust centrifugal switch/clean contact points. Replace

either if at fault.

9. Replace motor.

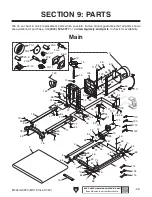

Summary of Contents for G0920

Page 60: ......