-26-

Model G0733 (Mfg. Since 10/11)

Always choose the correct spindle speed

for an operation. using the wrong speed

may lead to the workpiece being thrown at

high speed, causing fatal or severe impact

injuries.

2. open the front belt access panel, as shown in

figure 29.

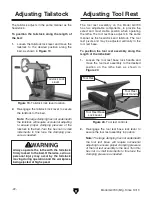

3. loosen the belt tension lock handle

(

figure 30).

figure 29. Belt access panel removed.

4. use the belt tensioning handle (figure 30) to

lift the motor assembly all the way up, then

re-tighten the belt tension lock handle—this

will hold the motor in place while you change

the belt position.

figure 30. motor tensioning handle and tension

lock handle.

Belt tensioning

handle

Belt tension

lock handle

5. reach into the belt access cavity and roll the

belt onto the desired set of pulleys, as shown

in

figure 31.

6. loosen the belt tension lock handle and

lower the motor.

7. apply downward pressure on the belt tension-

ing handle to properly tension the drive belt,

then re-tighten the belt tension lock handle.

Note:

When properly tensioned, the belt

should deflect about

1

⁄

8

" when moderate pres-

sure is applied to the belt mid-way between

the upper and lower pulley, as shown in

Figure 32

.

8. replace the front belt access panel.

figure 32. testing for

1

⁄

8

" belt deflection.

Pulley

Deflection

Pulley

figure 31. speed range belt positions.

Spindle

Motor

B

A

A

= High Range

330-3200 RPM

B

= Low Range

100-1200 RPM

Summary of Contents for G0733

Page 52: ......