Model G0733 (Mfg. Since 10/11)

-25-

headstock Faceplate

installing faceplate

To prevent the faceplate and workpiece sep-

arating from the spindle during operation,

the headstock faceplate MuST be firmly

threaded onto the spindle and secured in

place by fully tightening the two faceplate

set screws. if these instructions are not

properly performed, serious personal injury

could occur.

Note:

To remove the faceplate, disconnect the

lathe from the power source and perform the

steps above in reverse.

To install the faceplate:

1. disCoNNeCt lathe From poWer!

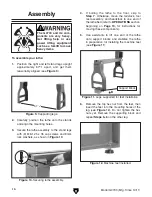

2. insert the indexing pin into one of the index-

ing holes and rotate the spindle until the pin

engages to prevent the spindle from turning

while you tighten the faceplate, as shown in

figure 26.

3. thread the faceplate onto the spindle until it

is snug.

4. using the included 4mm hex wrench, tighten

the two set screws along the inside diameter

of the faceplate to secure it to the spindle

(see

figure 26).

figure 26. locking spindle with indexing pin and

faceplate set screw location.

Faceplate set

screw (1 of 2)

changing Speed

Ranges

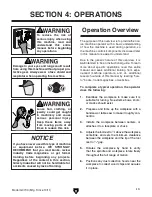

the model g0733 has pulley belt configuration

provided two speed ranges (see

figure 27).

Note:

To maximize spindle torque, use the low

spindle speed range for spindle speeds of 1200

RPM or less.

refer to the speed recommendations chart in

figure 28 to choose the appropriate rpm for your

operation. then choose the speed range that will

include the selected rpm.

Changing speed ranges

Diameter

of Work-

piece

Roughing

RpM

General

cutting

RpM

finishing

RpM

under 2"

1520

3200

3200

2–4"

760

1600

2480

4–6"

510

1080

1650

6–8"

380

810

1240

8–10"

300

650

1000

10–12"

255

540

830

12–14"

220

460

710

14–16"

190

400

620

figure 28. model g0733 speed

recommendations.

To change speed ranges:

1. disCoNNeCt lathe From poWer!

figure 27. speed range belt positions.

Spindle

Motor

B

A

A

= High Range

330-3200 RPM

B

= Low Range

100-1200 RPM

Summary of Contents for G0733

Page 52: ......