-22-

Model G0733 (Mfg. Since 10/11)

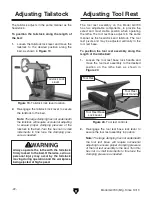

Adjusting Tailstock

the tailstock adjusts in the same manner as the

headstock.

To position the tailstock along the length of

the bed:

1. loosen the tailstock lock lever and move the

tailstock to the desired position along the

bed, as shown in

figure 19.

figure 19. tailstock lock lever location.

2. re-engage the tailstock lock lever to secure

the tailstock to the bed.

Note:

The large clamping hex nut underneath

the tailstock will require occasional adjusting

to ensure proper clamping pressure of the

tailstock to the bed. Turn this hex nut in small

increments to fine tune the clamping pres-

sure as needed.

Always operate the lathe with the tailstock

firmly locked to the bed. Otherwise, serious

personal injury may occur by the tailstock

moving during operation and the workpiece

being ejected at high speed.

tailstock lock

lever

Adjusting Tool Rest

the tool rest assembly on the model g0733

has two adjustable components, to provide the

safest and most stable position when operating

the lathe. the tool rest base adjusts in the same

manner as the headstock and tailstock. the tool

rest pivots and may be adjusted vertically in the

tool rest base.

To position the tool rest assembly along the

length of the lathe bed:

1. loosen the tool rest base lock handle and

move the tool rest assembly to the desired

position on the lathe bed, as shown in

figure 20.

tool rest

2. re-engage the tool rest base lock lever to

secure the tool rest assembly in position.

Note:

The large clamping hex nut underneath

the tool rest base will require occasional

adjusting to ensure proper clamping pressure

of the tool rest assembly to the bed. Turn this

hex nut in small increments to fine tune the

clamping pressure as needed.

figure 20. tool rest controls.

tool rest

tool rest

lock handle

tool rest Base

lock lever

Summary of Contents for G0733

Page 52: ......