Model G0733 (Mfg. Since 10/11)

-23-

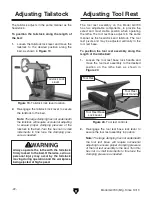

To adjust the angle or height of the tool rest:

1. loosen the tool rest base lock lever and the

tool rest lock handle to adjust the position of

the tool rest.

2. position the tool rest approximately

1

⁄

4

" away

from the workpiece and approximately

1

⁄

8

"

above the workpiece center line, as shown in

figure 21.

3. re-tighten the tool rest lock handle and the

tool rest base lock lever to secure the tool

rest in position.

Workpiece

Center Line

Distances

Tool Rest

1

⁄

8

"

1

⁄

4

"

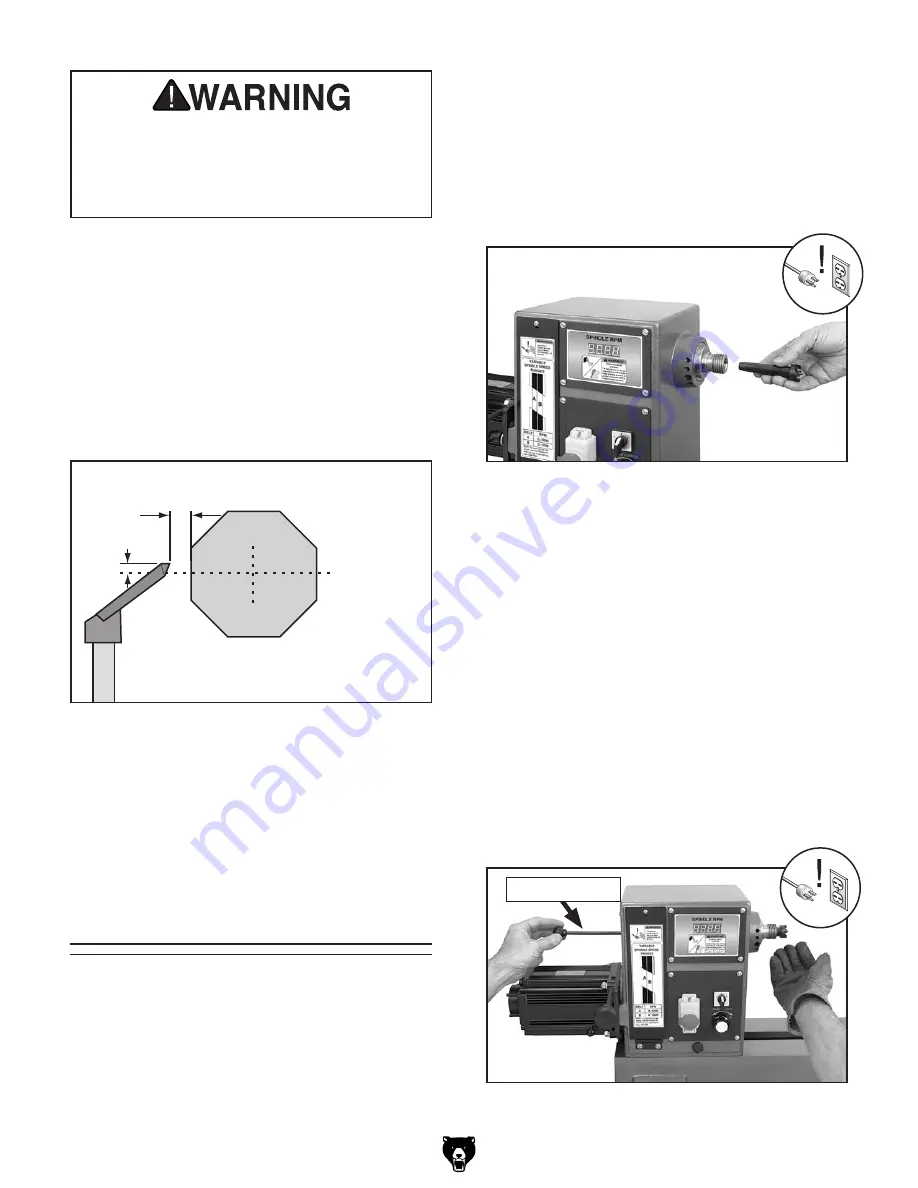

figure 21. tool rest position relative to

workpiece.

installing/Removing

Headstock center

the included spur center installs into the head-

stock spindle with an mt#2 tapered fit.

installing the Headstock center

1. disCoNNeCt lathe From poWer!

2. make sure the mating surfaces of the center

and spindle are free of debris and oily sub-

stances before inserting the center to ensure

a good fit and reduce runout.

3. insert the tapered end of the center into

the spindle, and push it in with a quick, firm

motion, as shown in

figure 22.

headstock Center

Removing the Headstock center

1. disCoNNeCt lathe From poWer!

2. hold a clean rag under the spindle or wear a

glove to catch the center when you remove

it.

3. insert the knockout tool through the outbound

end of the spindle and firmly tap the back of

the center, catching it as it falls, as shown in

figure 23.

figure 23. removing the headstock center.

Knockout tool

figure 22. installing center into the headstock

spindle.

4. make sure the center is securely installed by

attempting to pull it out by hand—a properly

installed center will not pull out easily.

Always operate the lathe with the tool

rest assembly firmly locked in position.

Otherwise, serious personal injury may

occur by the tool being pulled from the

operator's hands.

Summary of Contents for G0733

Page 52: ......