-4-

Model G0701 (Mfd. Since 9/17)

Controls &

Components

To reduce your risk of

serious injury, read this

entire manual BEFORE

using machine.

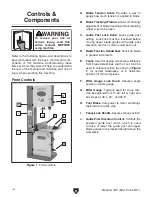

Refer to the following figures and descriptions to

become familiar with the basic controls and com-

ponents of this machine. Understanding these

items and how they work will help you understand

the rest of the manual and minimize your risk of

injury when operating this machine.

A. Blade Tension Scale: Provides a way to

gauge how much tension is applied to blade.

B. Blade Tracking Window: Allows monitoring/

adjustment of blade tracking without requiring

wheel cover to be open.

C. Guide Post Lock Knob: Locks guide post

setting. Lock knob must be loosened before

moving upper blade guides with guide post

elevation control, or motor could burn out.

D. Blade Tension Handwheel: Tensions blade

in gradual increments.

E. Fence: Used for ripping or resawing. Distance

from blade determines width of cut. Can be

used in vertical position (as shown in

Figure

1) for normal workpieces, or in horizontal

position for thin workpieces.

F. Miter Gauge Lock Knob: Secures angle

position of miter gauge.

G. Miter Gauge: Typically used for cross cuts.

Can be adjusted from 0°–60° left or right, and

has stops at 45°L, 90°, and 45°R.

H. Foot Brake: Cuts power to motor and brings

the blade to a quick stop.

I. Fence Lock Handle: Secures fence position.

J. Guide Post Elevation Control: Controls the

powered guide post motor, which is used

to raise or lower the guide post and upper

blade guides to the desired height above the

workpiece.

Front Controls

Figure 1. Front controls.

B

D

A

C

E

J

F

G

H

I