-20-

Model G0700 (Mfd. Since 5/14)

4. Remove the red lifting bolts from the back of

the table.

5. Place a level on the cast iron table to level

the table saw cabinet side to side and front

to back. This will allow the table to slide

smoothly.

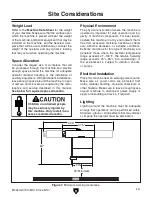

Note: There are three options for leveling the

saw: 1) Place it on a mobile base (Grizzly

Model G7315Z) and use the mobile base

adjustable feet to level it, 2) shim under the

cabinet, and 3) thread bolts down into the

nuts that are welded on the inside stand cor-

ners (see

Figure 9).

Figure 9. Hex bolt in stand corners for leveling;

the hex nut is used to secure the bolt position.

DO NOT lift the table saw any higher than

necessary to clear the floor. Serious per-

sonal injury and damage to the machine

may occur if safe moving methods are not

followed.

Figure 8. Lifting the table saw with a forklift and

lifting straps (sliding table removed for clarity).

This machine and its

components are heavy.

Serious injury may occur

if safe moving methods

are not followed.

Get help when lifting or

moving the machine and

its components. Use a

forklift to reduce the

risk of a lifting strain or

crushing injury.

If a forklift is not available, a MINIMUM of four

strong people are required to move this table saw

from the pallet. The table saw can be "walked" off

the pallet, then moved into place with a dolly or by

sliding it. An additional option would be to put the

saw on a Model G7315Z mobile base, so it can be

easily moved around the shop (see

Page 56).

To remove the saw from the pallet:

1. Remove the motor cover

2. Feed the lifting straps around the lifting red

bolts on the back of the table and the sliding

table saw mounts on the front of the cabinet

(see

Figure 8). Attach the ends of the lifting

straps to the forklift forks.

3. Lift the table saw cabinet only as high as nec-

essary to clear the pallet, and move it to the

desired location.

Lifting & Placing

Summary of Contents for G0700

Page 17: ...Model G0700 Mfd Since 5 14 15 Hardware Recognition Chart...

Page 85: ......