g0650 Welding downdraft table

-17-

SEcTION 5: MAINTENANcE

For optimum performance from your machine,

follow this maintenance schedule and the instruc-

tions given in this section. always wear an osha

approved respirator when cleaning this machine.

Daily check/Maintenance:

•

Check suction hose for leaks.

•

Clean slag catch and screen as required.

•

inspect and correct for any other unsafe

condition.

•

inspect welding area before and after weld-

ing or cutting operations for fire hazards and

smoldering combustibles.

Schedule

Cleaning the Model g0650 is relatively easy.

Wear an osha approved respirator and vacuum

excess dust with a shop vacuum fitted with a

hepa filter. Wipe off the remaining dust with a

damp cloth. do not use harsh detergents or sol-

vents on the cabinet.

cleaning

When servicing filters, wear appropriate

respirators and body protection. When

vacuuming filters and cabinet, only use a

shop vacuum that is equipped with a hEpA

filter, or dangerous particles may be spread

throughout your shop and contaminate the

air. Wrap all waste filters in air-tight plastic

bags, mark and dispose of according to

current laws and regulations.

the Model g0650 has a high-quality 1-2mm stain-

less steel screen. Make sure that you clean this

screen often and inspect for holes or damage.

Tools Needed

Qty

Leather gloves and safety goggles ..........1 pair

Wire Brush ......................................................... 1

osha approved respirator .............................. 1

shop Vacuum w/hepa Filter ............................ 1

Wire Brush ......................................................... 1

To clean the screen:

1. Wearing a respirator, eye protection, and

heavy leather gloves, remove the vented

work table and set it aside.

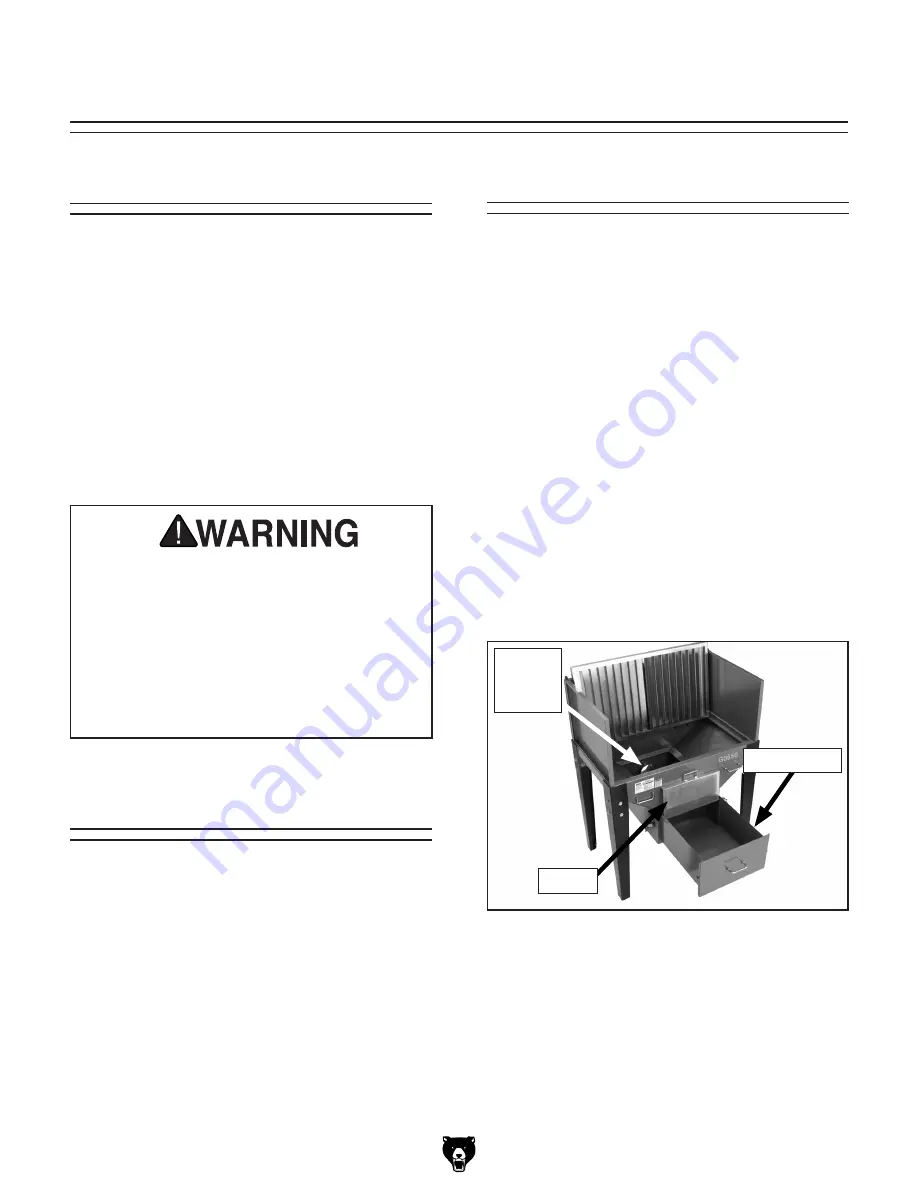

2. Unlatch and remove the slag drawer and

slide the screen up and out (

Figure 17).

Screen cleaning

3. tap the screen and carefully use a wire brush

to brush away built up dust or slag. if any

solder or slag has welded itself to the screen,

do not pry it off or you may put a hole in the

screen.

4. Vacuum the loose dust in the cabinet and

slag drawer; and reinstall the screen, drawer,

and the vented work table.

Figure 17. Cover and stainless screen.

screen

internal

suction

port

slag drawer