-48-

Model G0634X (Mfd. Since 11/20)

Checking Planer

Table Parallelism

Table Parallelism Inspection

The easiest way to check that your planer table is

parallel with the headstock is to plane a workpiece

and then measure its thickness in multiple loca-

tions. Extra care must be taken to ensure accu-

racy. If the workpiece is tapered from left-to-right

or from front-to-back, then parallelism may be a

problem. If the table is not within the maximum

allowable tolerances, it must be adjusted.

Table Parallelism Adjustments

Items Needed:

Qty

Rotacator ........................................................... 1

Wrench 12mm ................................................... 1

Hex Wrench 4, 8mm ....................................1 Ea.

To adjust table parallelism:

1.

DISCONNECT MACHINE FROM POWER!

2.

Raise planer table as far as possible.

3.

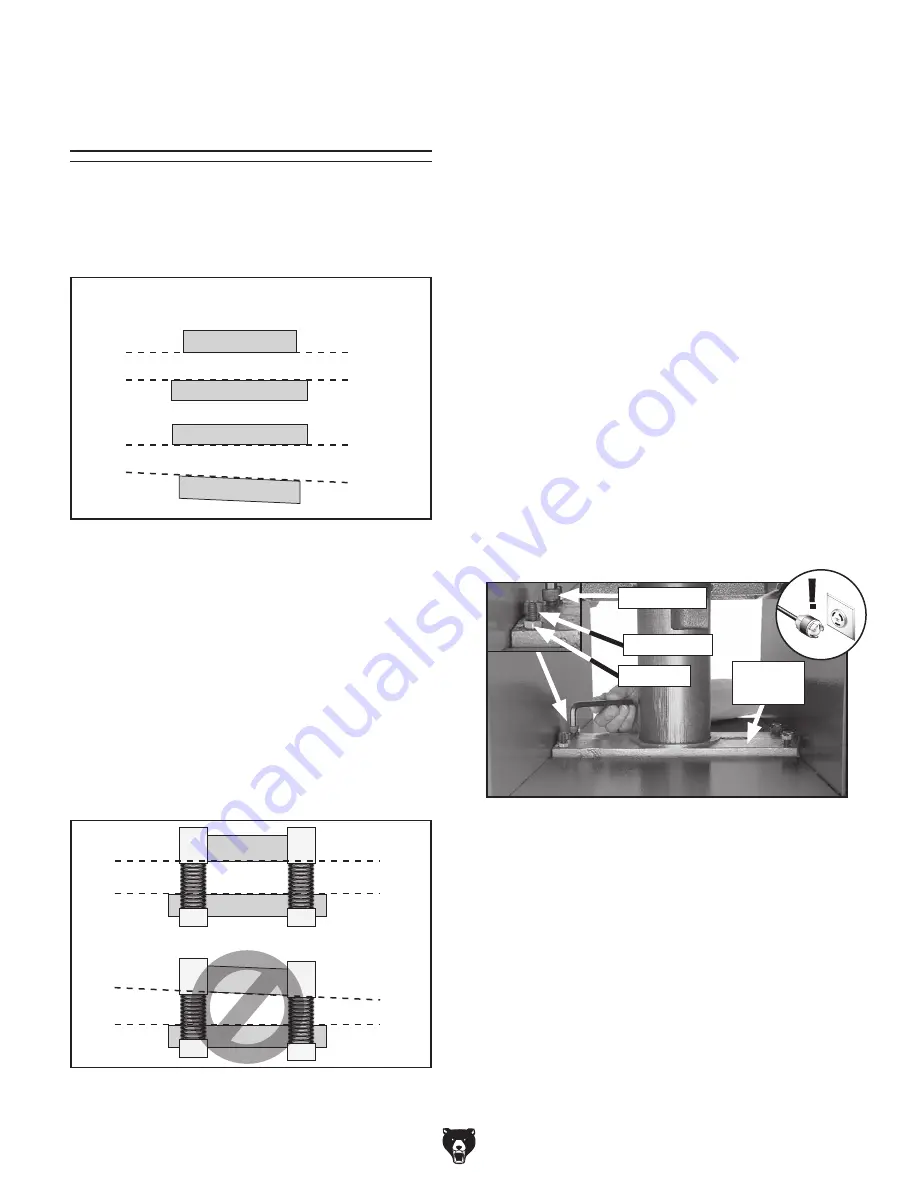

Loosen (4) cap screws on cylinder liner, as

shown in Figure 69.

Table parallelism is critical to the operation of the

planer. As such, it is essential that the planer table

is parallel with the cutterhead (within 0.002") from

side-to-side, as illustrated in Figure 67.

Figure 67.

Side-to-side parallelism of table and

cutterhead.

Cutterhead

Table

Parallel

Parallel

SIDE-TO-SIDE

Table

NOT Parallel

NOT Parallel

(Front View)

Cutterhead

Figure 68.

Front-to-back parallelism.

Table

Table

Head

Head

Parallel

Parallel

Not-Parallel

Not-Parallel

FRONT

BACK

How the planer table sits in relation to the head

casting from front-to-back is also important (see

Figure 68

). The tolerances on the front-to-back

positioning are not as critical as the cutterhead/

table side-to-side positioning. Therefore, the max-

imum allowable tolerance for the front-to-back

parallelism is not more than 0.020".

— If table is not parallel to cutterhead side-to-

side (see Figure 69), loosen (2) lock nuts

on right or left side of cylinder liner. Adjust

set screws to raise or lower table so it is

parallel to cutterhead.

— If table is not parallel to cutterhead front-

to-back (see Figure 69), loosen (2) lock

nuts at front or back of cylinder liner.

Adjust set screws to raise or lower front or

back of table so it is parallel to cutterhead.

4.

Tighten (4) cap screws on cylinder liner.

Figure 69

. Adjusting table parallelism.

Lock Nut

Set Screw

Cap Screw

Cylinder

Liner

Maximum Allowable Tolerances:

Cutterhead/Table Side-to-Side ..................0.002"

Head Casting/Table Front/Back ................0.020"

Summary of Contents for G0634X

Page 68: ......